- Details

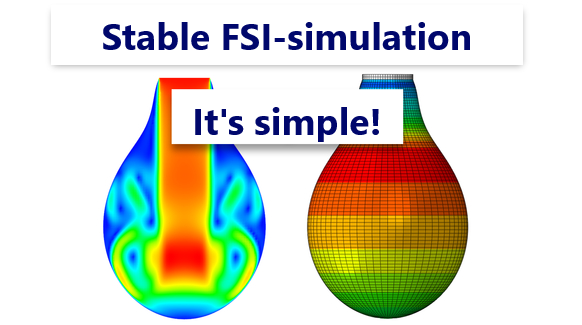

The future belongs to FSI simulations! It's no secret that co-simulation, CFD + FE, is becoming more and more in demand. Such modeling, covering both body deformations and hydro-gas dynamics, allows to obtain more accurate and reliable results in the fields of aircraft engineering, automotive, biomechanics and many others.

- Details

Our Team represents article about Stabilization methods of co-simulation on the example of filling air balloon with water.

- Details

In this article we will talk about our new convenient functionality in FV3.13.01 – an inp-file editor for FlowVision co-simulation with an external finite element software package.

- Details

And an example FlowVision project: "Simulation of flow of water with sand"

How to model particles?

If you find yourself asking this question, then you should know that we and the FlowVision user guide are with you. On a more serious note, the topic of modelling dispersed phases has already indirectly come up in articles on multiphase flows and icing. And the non-trivial examples of coal combustion and droplet evaporation have been covered step-by-step in the tutorial.

Nevertheless, dispersed problems are diverse and hold many questions. It's time to bring clarity to particle modelling! Over the course of our dive into the topic of dispersion, we will focus on key settings, talk about the current capabilities and limitations of FlowVision, and examine projects "from the inside".

- Details

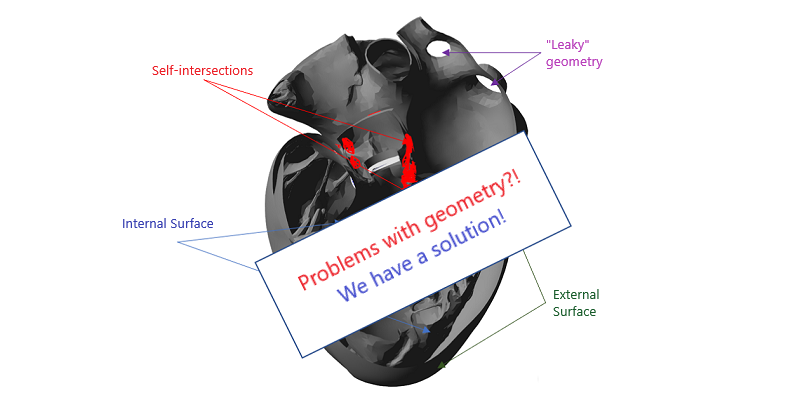

To make life a little easier for a beginner in FSI, we have prepared a checklist of steps that are standard to all FSI projects. In reality, this is just the tip of the iceberg, since each project has its own specific characteristics.

What does one need to know in order to run joint calculations?

The answer to this question is not that simple. Let's go through the checklist together and reveal all the subtleties and "secrets" at each step.

- Details

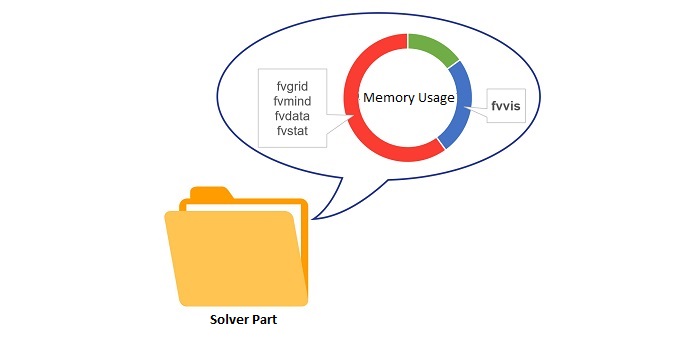

Fvvis files are convenient because they allow you to reduce disk space taken up by the solver part of the project. Let's consider that the solver parts of serious industrial and scientific simulations can "weigh" dozens of GB. What if there are several such simulations, and for each the user would like to store results files? We have a solution - fvvis files!

In most cases, users spend large memory resources storing frequent data about the grid parameters, the magnitude of equation residuals, the size of the calculated step, etc. But this data is only necessary to restore a project to that time or to resume a simulation. When you just need to save visual results (layers with parameter distributions) this excess data is redundant. For this purpose, fvvis files are the optimal solution for data storage.

- Details

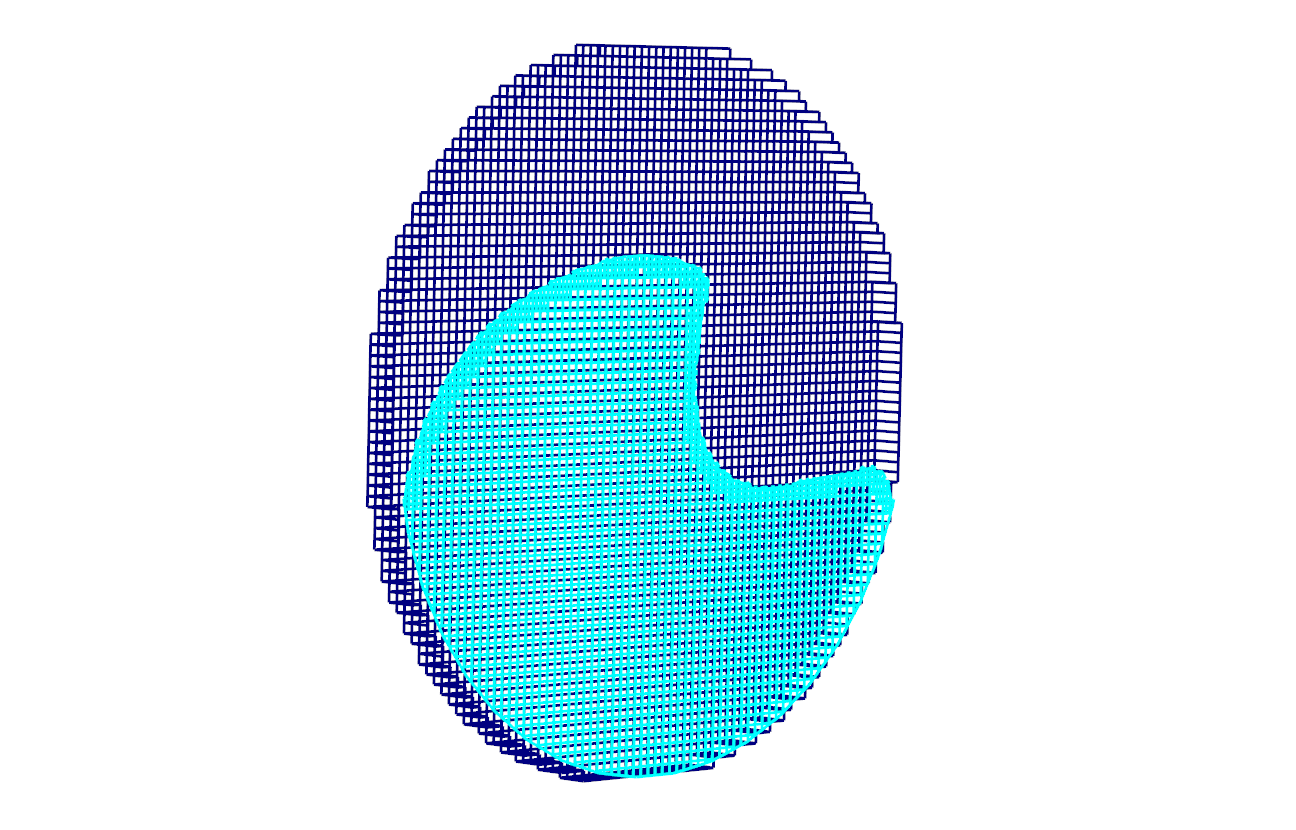

In this article we will be discussing the computational grid. FlowVision uses a structured locally adaptive mesh with sub-grid resolution of geometry, predominantly consisting of hexagonal cells. The computational grid is constructed automatically. The accuracy of the mesh refinement of a geometric model of any complexity is ensured by using a technology for sub-grid geometry resolution.

If you would like to know more, read on for our answers to the 5 most frequent questions about the FlowVision grid:

1. How to construct a computational grid in FlowVision?

2. What is "adaptation" of the computational grid?

3. How to evaluate mesh quality in FlowVision?

4. I have a complex geometric model. How can the FlowVision mesh ensure accuracy of the calculation in boundary cells?

5. The computational grid and moving bodies: how do they interact during the computation process?

- Details

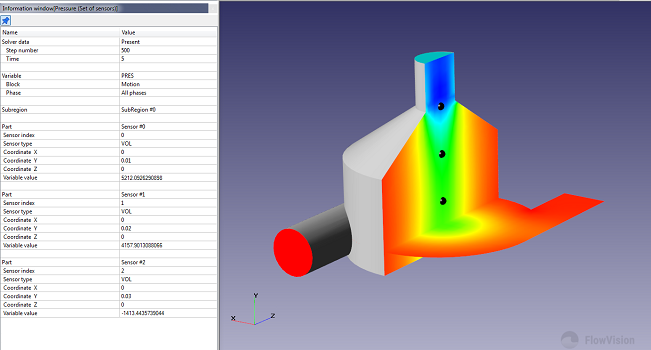

Characteristics are one of the most powerful tools in the FlowVision software complex for obtaining information about the calculation.

Characteristics can be used to:

- obtain calculation results, such as: flow rate, pressure, temperature, or forces acting on a surface or in a volume section

- monitor calculation results, outputting the data as a graph within the program interface

- debug the project / diagnose problems (for example, by finding extreme values within the computational space).

- Details

Advanced users of FlowVision are certainly familiar with the trick of using a remote non-computational subdomain for 2D simulations that utilise grid adaptation. This non-obvious method is used to disable mesh adaptation along one coordinate direction, thus making sure there will be only one cell across the width of the computational space. Despite being complicated, the trick works and helps to minimize computational mesh in 2D simulation.

In the new release of FlowVision, the 2D-simulation option is built into the program interface. Now you can create a project with 2D adaptation in just one click. Furthermore, the creation of projects with a 2D-sector condition has become easier.

You can try it! In this article we'll be talking about why it's so important to first perform a 2D calculation instead of directly jumping into a 3D one.

- Details

For the first time in our blog - the whole article is devoted to the FVTerminal module! If you want to speed up and automate the start of your simulations, then you just need to get acquainted with its capabilities.

FVTerminal allows you to perform certain operations while bypassing FVPPP, and can also do other cool things:

- start and stop calculation (on local and remote computers)

- download the client part of the project form the server part data

- delete projects permanently

- connect to the Solver via the Viewer

- and most interesting of all - queue projects

- Details

Today's topic is not how to obtain and install FlowVision license - this information can be found in our earlier blog articles or requested from our sales manager. Let's talk instead about when you would need a FlowVision license and when you can work without one. And also a little about licensing options and the error "No free licenses for this user".

- Details

Welcome to the FlowVision users team! Before you start creating your first project, you need to download the distribution pack and prepare it for work. In this article, we will tell you how to do this, so you can begin simulation of your engineering tasks as quickly as possible.

Here are the steps that will help get you absolutely prepared to run local FlowVision simulations on PC:

Step 1: Download FlowVision and License Manager

Step 2: Install FlowVision and License Manager

Step 3: Register the license

Step 4: Create Solver-Agent user

Step 5: Check the license settings