Clearances and leakages through them play a vital role in determining the efficiency of positive displacement machines, especially of screw compressors. It is of interest to accurately predict the overall machine behavior including the leakage flows, even during the early design phases. CFD (Computational Fluid Dynamics) methodologies can potentially address this problem; however, the computational efficiency is limited by the well-known issue: dimensionality. This issue arises due to the fact that rotors are sized in tens of centimeters whereas the clearances are in the order of (sub) microns.

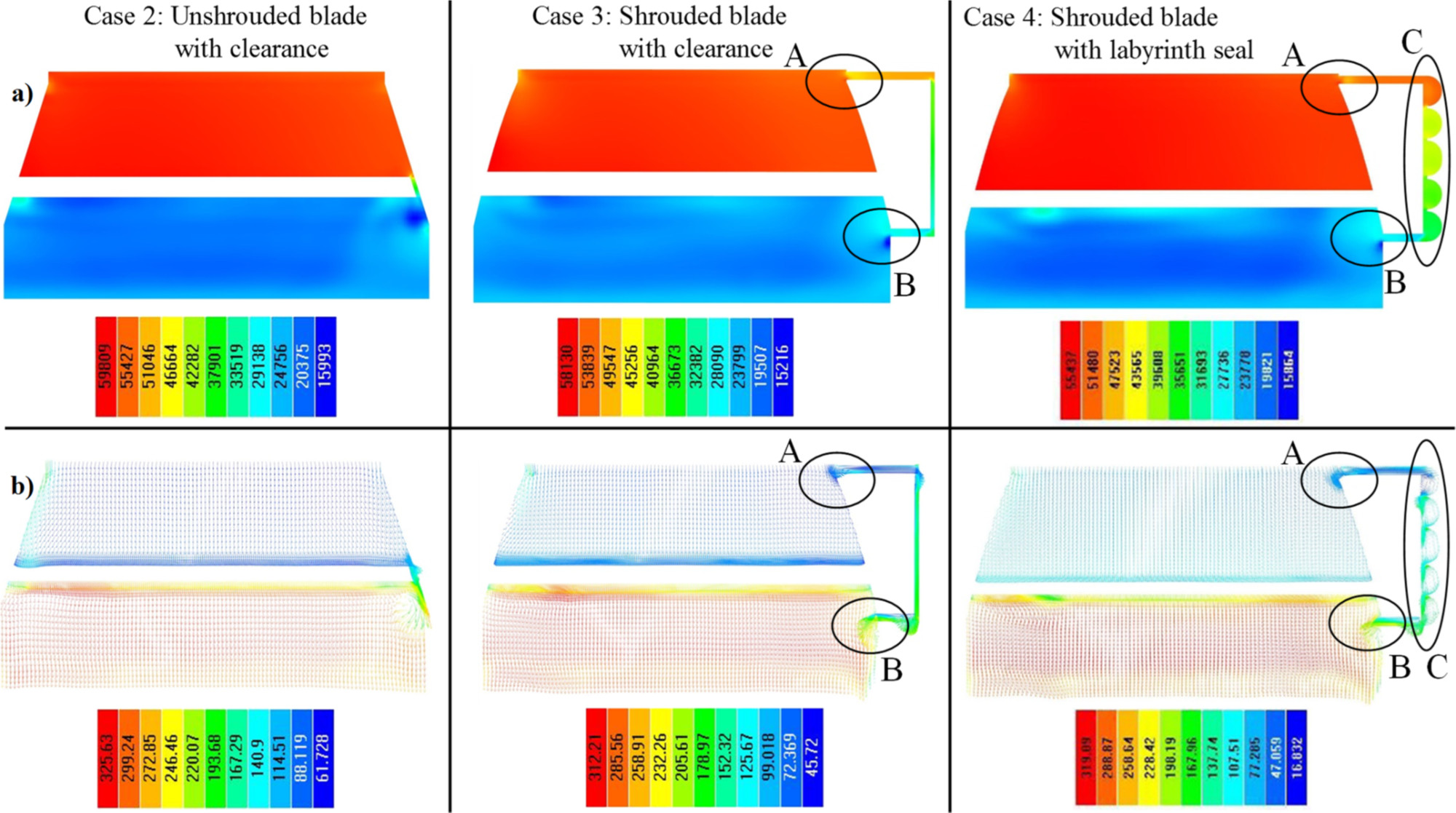

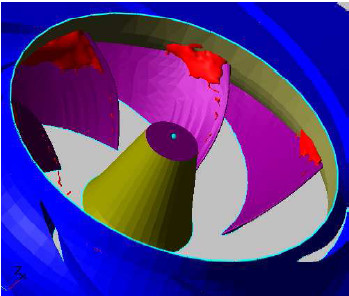

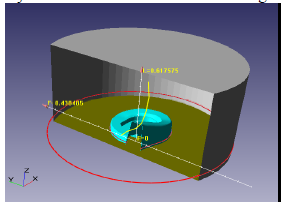

In this study, blade tip leakages were calculated for aIn this study, blade tip leakages were calculated for a Radial Outflow Turbine (ROT) designed for an Organic Rankine Cycle (ORC) at a 150kW power output. Since the turbine blade sizes are relatively very small for low-capacity systems, the leakages through the blade tip clearance considerably affect the turbine isentropic efficiency. Therefore, labyrinth seals were applied at the blade tips and the ROT’sperformance degradation due to blade tip leakages was investigated. In order to determine the preliminary ROT sizes, an in-house developed 1-D code was utilized.

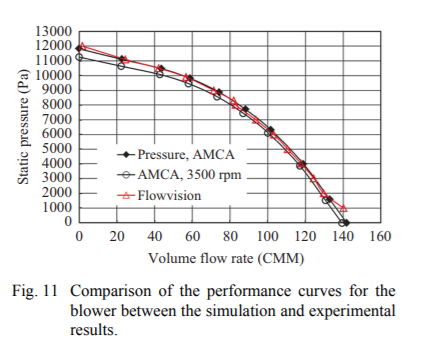

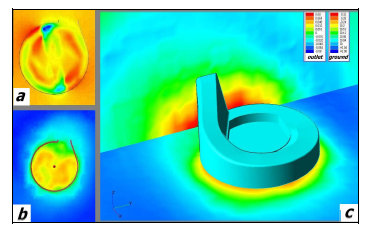

As the consciousness of energy saving and carbon reduction and comfortable environment is paid increasing attention to, the common objective of various countries with decreasing energy is to develop and popularize high efficiency and low running noise blowers. This study uses CFD to calculate the flow field and performance of a blower and compare with the experimental measurement.

The characteristic curve of blower shows that the simulated and experimental values are close to each other, the difference between the values is only 0.4%. This analysis result proofs the CFD package is a highly reliable tool for the future blower design improvement. In addition, this study discusses the noise distribution of blower flow field, the periodic pressure output value calculated by CFD is used in the sound source input of sound pressure field, so as to simulate and analyze the aerodynamic noise reading of the flow field around the blower. The result shows that the simulated value of flow field around the fan has as high as 80.5 dB(A) ~ 81.5 dB(A) noise level and is agree with measurement (82 dB(A)). The noise level is low but has a sharp noise. According to the numerical results, designer of the blower modify the tongue geometry and remove the sharp noise.

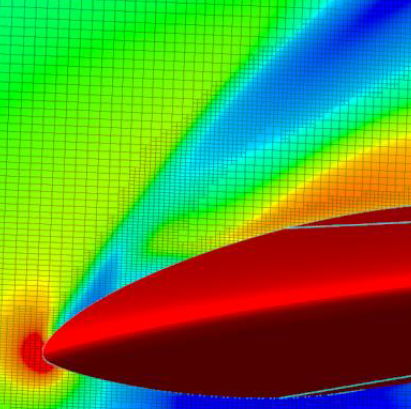

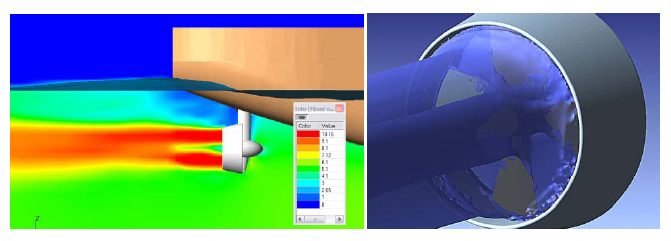

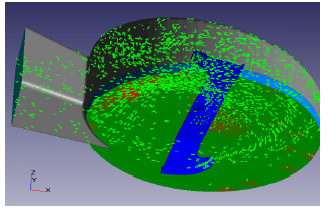

CFD calculations of NREL Phase VI rotor under wide range of operation conditions were conducted using FlowVision software. Computations were performed for various wind speeds with axial inflow, constant RPM and constant blade pitch. The rotation of the blades was modeled via different approaches; steady-state with frozen rotor using rotating reference frame and transient with moving boundaries or sliding surfaces. In addition to this, an ‘Overlapping Boundary Layer (OBL)’ was implemented to resolve the boundary layer for a selected case. Turbulence models ‘k-ε-AKN and k-ω Shear Stress Transport (SST) were used and compared. Except the OBL case, FlowVision wall function approximation was employed for all calculations with y+ values between 30 and 100.

Overall results were compared for all of the above-mentioned numerical approaches and showed good agreement with the experimental data. k-ω SST turbulence model is found to perform better to predict stall onset. The stall occurrence and general torque trend as a function of wind speed is fairly well captured. Comparisons of the static pressure distribution around blades with experimental data at different span-wise sections for different wind speeds are presented and good agreement is observed.

The FDA (U.S. Food & Drug Administration) has partnered with academia and industry the Critical Path Initiative program to create a Guidance Document for industry-wide use proper validation and use of CFD models in the assessment of medical device safety.

CFD simulations are increasingly being used to determine flow patterns and fluid forces in order to evaluate blood-contacting medical devices. It is due to its potential to calculate the values of physical parameters that may affect the level of blood damage the device may cause, such as shear stress or dwell time. Although CFD can decrease the need for expensive prototyping and laboratory testing, there are no standardized and reliable methods available for using CFD techniques in this field.

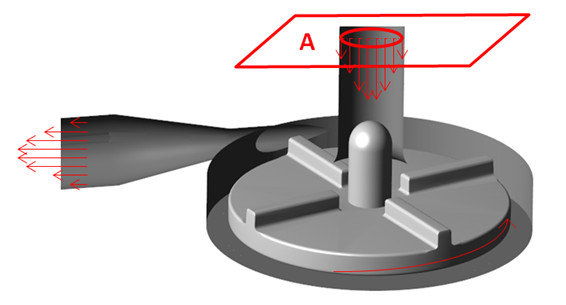

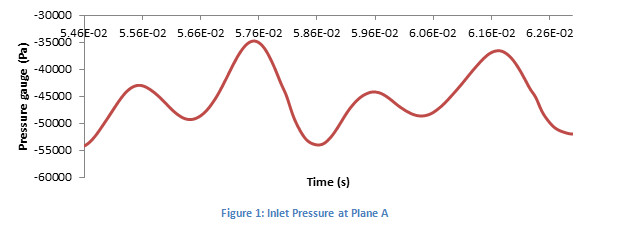

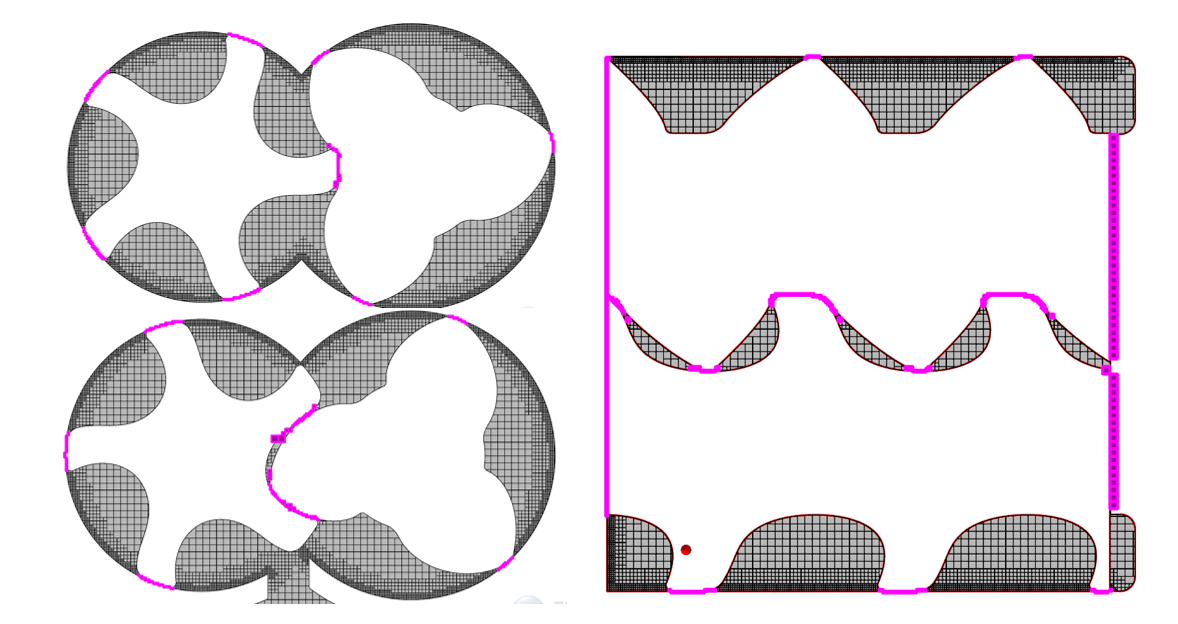

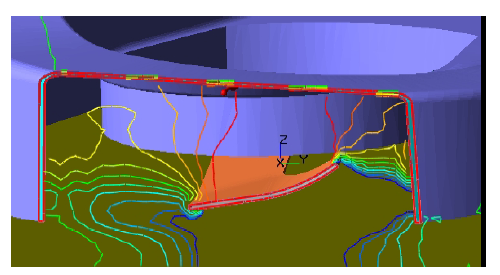

The purpose of this project is to determine the limits of the applicability of CFD techniques by comparing some parameters (such as gauge pressure or shear stresses) of the computational simulations of a blood pump in several working conditions against suitable experimental models. The different conditions included a wide range of velocity profiles at the inlet or different rotor velocities.

FlowVision moving body capability, together with the real CAD geometry import, has allowed the numerical simulation of this complex case with a relatively simple mesh. Time-dependent results during a whole revolution of the rotor have been obtained, providing consistent and more realistic data for the different scenarios. As example, variables as the pressure gauge behave cyclic with a period of a 1⁄4 of the revolution time, which is consistent with the number of blades.

The constant grows of the motor fuel prices increases the requirements to the quality of ship propulsion study on the design stage. Some unusual approaches that applied during development of the "Volgo-Donmax" class ship project are described in this article.

The noise of domestic machines including lawnmowers becomes an urgent issue. As the technology matures, designers need better tools to predict performance and efficiency of these machines across a wide range of operating conditions and find optimal ways to reduce noise.

Experiments fulfiled in CETIM have shown that tonal blade-passing-frequency (BPF) noise becomes predominant for lawn-mowers with a big rotor diameter. 2-D and 3-D CFD unsteady computations give a clear picture of pseudo-sound perturbation inside the casing of lawn-mower. Method of representation of unsteady motion of compressible fluid with subsonic flow as a sum of vortex mode (pseudo-sound) and acoustical mode (airborne sound) is used to define the sound near field.

Due to a current trend of increasing rotational speed and power, the problem of tone noise and pressure pulsation in centrifugal ventilators becomes a more urgent issue. Often the level of tones determines noise characteristics; mainly these are blade-passing frequencies (BPF).

In order to supply tools for low noise design to the manufacturers of lawnmowers CETIM has set up a research project on blade noise (which is predominant on medium size and big machines). Experimental studies are based on the use of a special test rig which allows to measure blade noise without disturbances from the drive unit and to determine simultaneously the pressure fluctuations generated by the blade.

CFD analysis of two first - stage centrifugal impellers is undertaken with the main goal to obtain additional evaluation data regarding flow characteristics of the old first stage impeller design and in the proposed new cantilever impeller design.