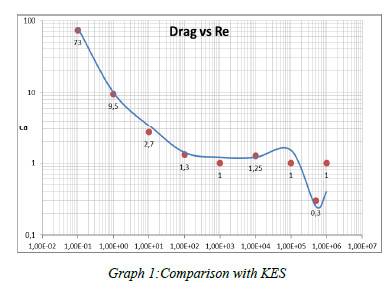

CFD analysis of flow over a cylinder for different Reynolds Numbers is explained in this paper by using different turbulence models.

During operation of vertical cylindrical tanks for storage of oil and oil products significant quantities of compacted sediments can be formed and accumulated. As a result, tank useful capacity, tank farm turnover are reduced, oil storage cost is increased due to the

necessity to put tanks out of operation and perform their cleaning.

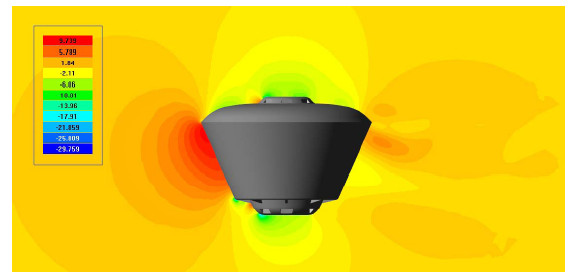

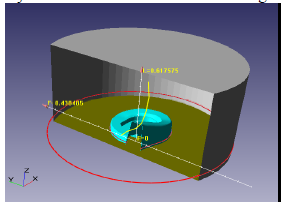

Feeder is one of the airships of the Multibody Advanced Airship for Transport (MAAT) system, under development within the EU FP7 project. MAAT is based on a modular concept composed of two different parts that have the possibility to join; respectively they are the so-called Cruiser and Feeder, designed on the lighter than air principle.

In order to supply tools for low noise design to the manufacturers of lawnmowers CETIM has set up a research project on blade noise (which is predominant on medium size and big machines). Experimental studies are based on the use of a special test rig which allows to measure blade noise without disturbances from the drive unit and to determine simultaneously the pressure fluctuations generated by the blade.

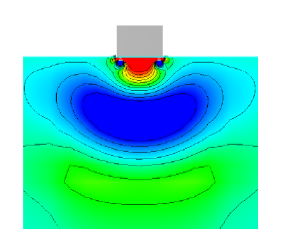

The paper presents a numerical simulation of the drop test in a still water for the multi-component box structure. The complexity of the problem is in the strong fluid-structure interaction (FSI) between the box and the water free surface. The numerical simulation of the drop test is performed with two software tools: Abaqus and FlowVision through the direct coupling interface, which manipulates, on the Abaqus side the Lagrangian finite-element mesh and on the FlowVision side the Eulerian finite-volume mesh with subgrid geometry resolution.

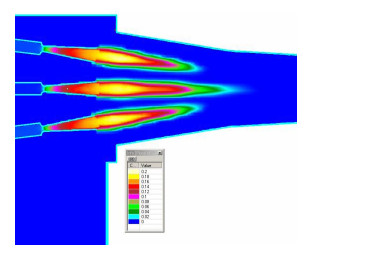

Computational results of 3D turbulent compressible gas flow in a single-nozzle ejector are compared with experimental data. Full Navier-Stokes equations and k- model of turbulence are used for mathematical model of gas flow. In computations the suction gas flow rate was determined and compared with experimental one. Two computational grids – coarse and fine are used to perform simulation.

Computation of the ship hull flow with the help of complexes of hydrodynamical analysis now gets the increasing practical value in the domestic and foreign design organizations.

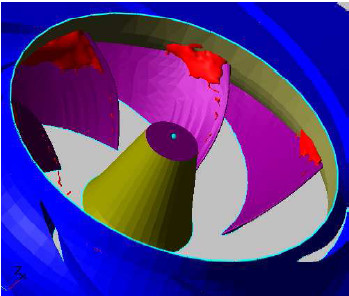

CFD analysis of two first - stage centrifugal impellers is undertaken with the main goal to obtain additional evaluation data regarding flow characteristics of the old first stage impeller design and in the proposed new cantilever impeller design.

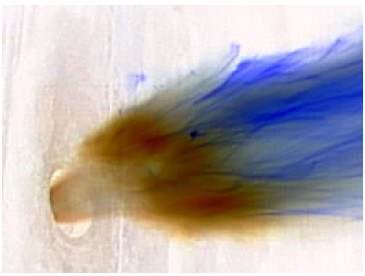

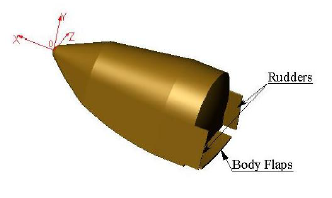

At present time RSC Energia is carrying out research work on designing the reentry manned spacecraft of new generation to crew deliver, in-flight support and return. The spacecraft ought to take the place of Soyuz. Manned spacecraft Clipper having the reentry vehicle (RV) of lifting body type is a possible alternate solution (Fig. 1). In comparison with Soyuz suggested RV provides higher maneuverability and less overloading during descent phase.

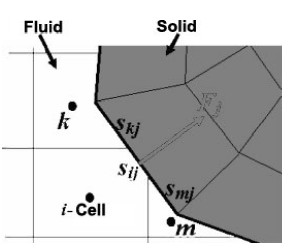

An advanced finite-volume method (method of modified finite volumes) for numerical simulation of flows in industrial applications and its implementation in code FlowVision is proposed. The method is based on non-staggered Cartesian grid with adaptive local refinement and a subgrid geometry resolution method for description of curvilinear complex boundaries. Semi-Lagrange approach for solution of convective transport equation and splitting algorithm for

solution of Navier-Stokes equations are presented.

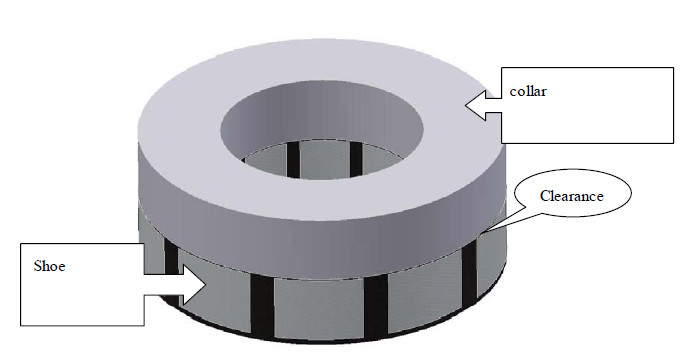

Lift force formation in a thrust bearing of 800-tons rotor of electric power station is discussed in the given paper. The problem is solved numerically. Direct coupling between finite-element system Abaqus calculating stress and strain state of an bearing parts and finite-volume system FlowVision-HPC calculating oil flow in gap between a collar and a shoe of bearing is used. The shape of the gap between the shoe and the collar, the clearance value, the moment of the friction force, and the temperature distribution of oil over the clearance are determined.

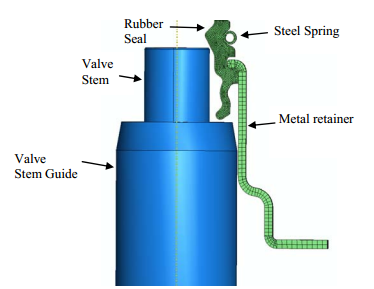

The first valve stem seal was invented in 1958. It was made up of Buna-N (NBR) Elastomer Body, Ring retainer, Teflon insert working in a 400°F temperature environment. In the early days before the invention of valve stem seals, there was higher oil consumption, excess blow by through the valves and high wear of the valves.