FlowVision 3.15.01 has been released on May 28, 2025. This post gives an overview of what's new.

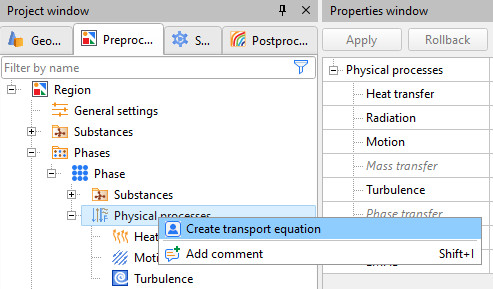

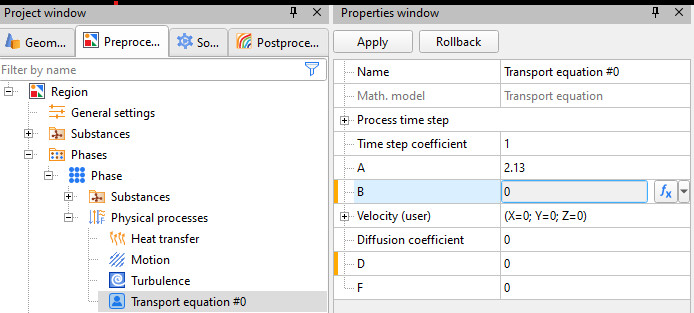

User Defined Physical Processes

FlowVision 3.15 introduces a universal physical process editor, allowing users to define their own mathematical models using transport equations of convection, diffusion, and reaction. This enables implementation of novel processes such as thrombus modeling, residence time analysis, and industrial processes like vulcanization. Coefficients and constants are handled through the formula editor.

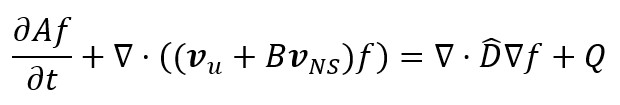

Quemada Non-Newtonian Viscosity Model

A Quemada viscosity law is now available, expanding non-Newtonian fluid modeling. This model is particularly important for cardiovascular simulations, as it captures patient-specific blood flow characteristics.

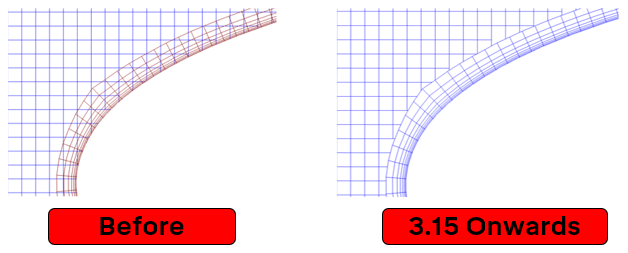

Integrated Boundary Layer Grid

The boundary layer grid is no longer an overlapping mesh but is integrated into the main grid. This improves calculation stability and accuracy near surfaces, especially where flow separation occurs.

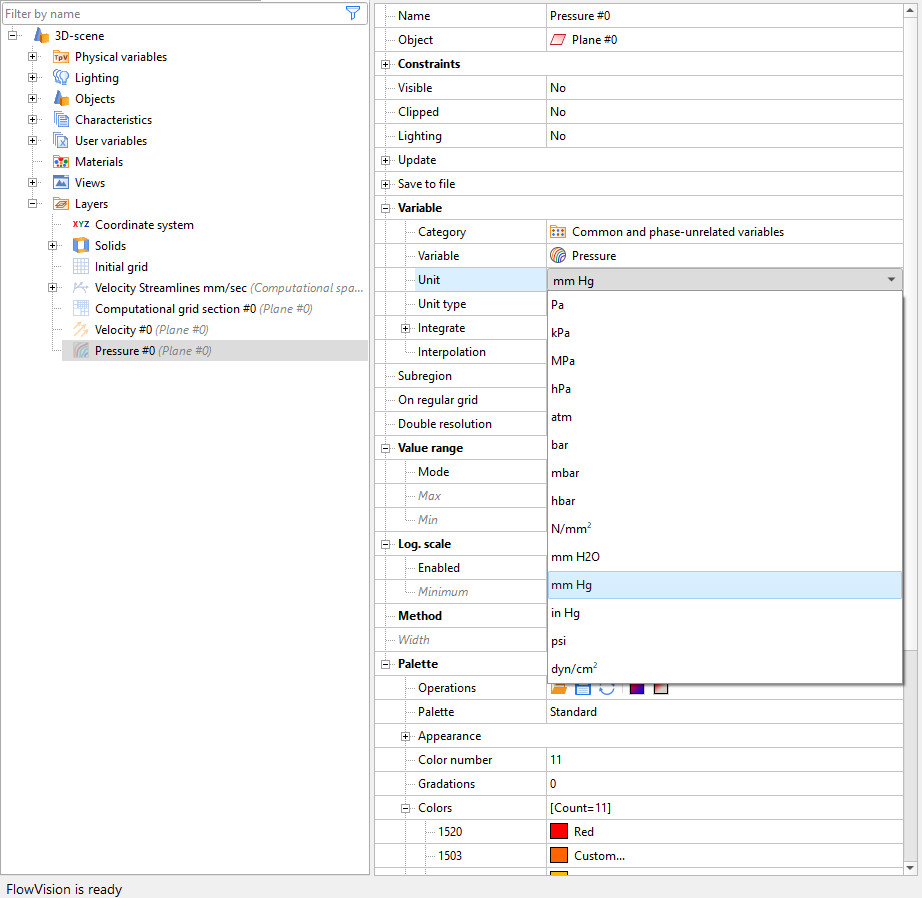

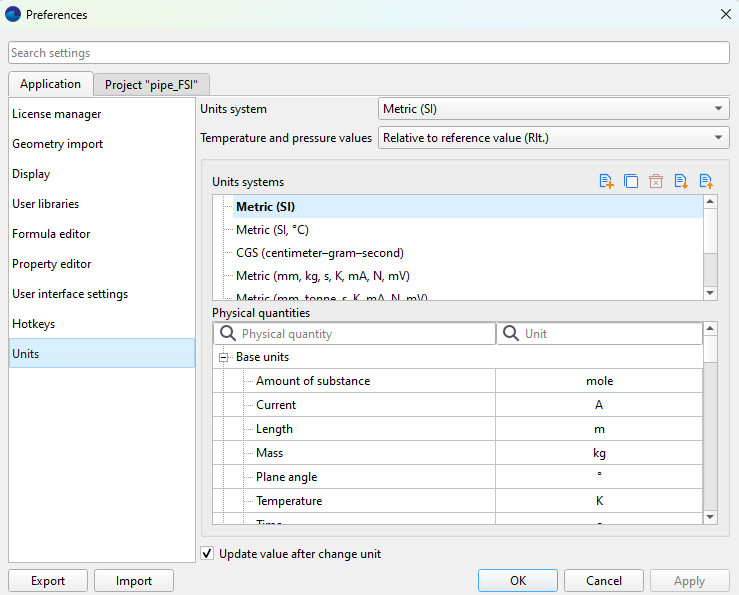

Flexible Unit System

Every physical quantity now carries its own dimension. Users can select from SI, CGS, or custom units, build their own unit packages, and apply them to projects. Automatic conversion ensures consistency across simulations.

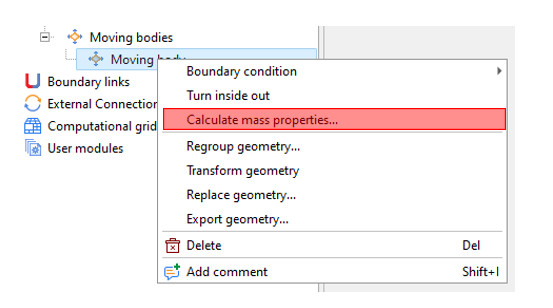

Automatic Calculation of Mass Properties

FlowVision can now automatically calculate mass, center of mass, and moments of inertia for moving bodies based on density and geometry. This is valuable for naval and mechanical heart valve applications.

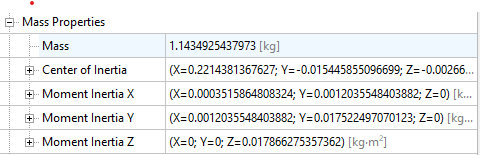

Spectral Properties of Particles

Particle modeling has been expanded to include spectra for parameters such as velocity, temperature, and volume fraction. Multiple spectra can be defined for use as boundary or initial conditions.

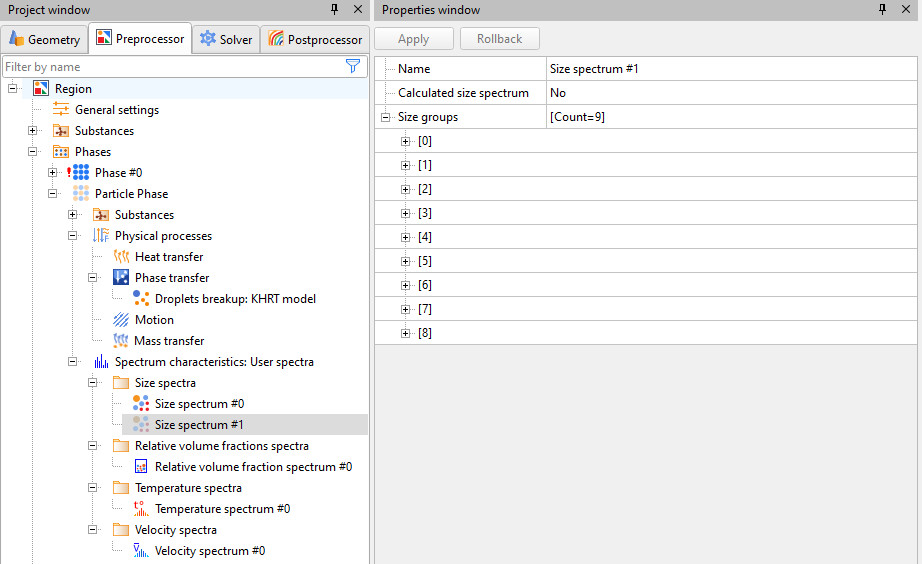

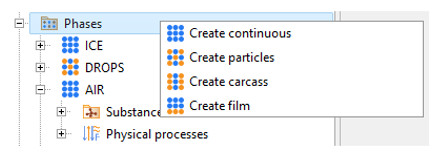

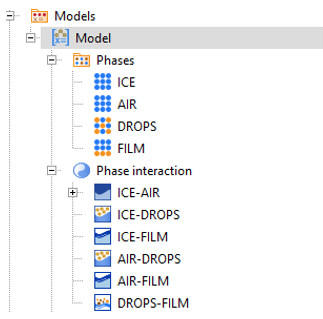

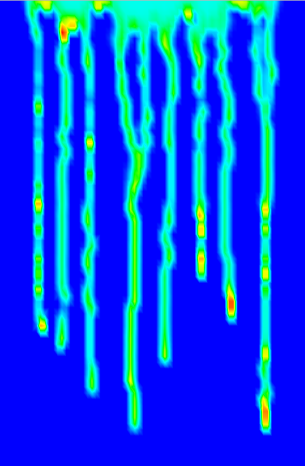

Film Phase & Interfaces

A new Film phase has been added, supporting simulations of film flows (e.g., icing, crystallization). The model includes film–phase interactions, customizable boundary conditions, and phase transitions.

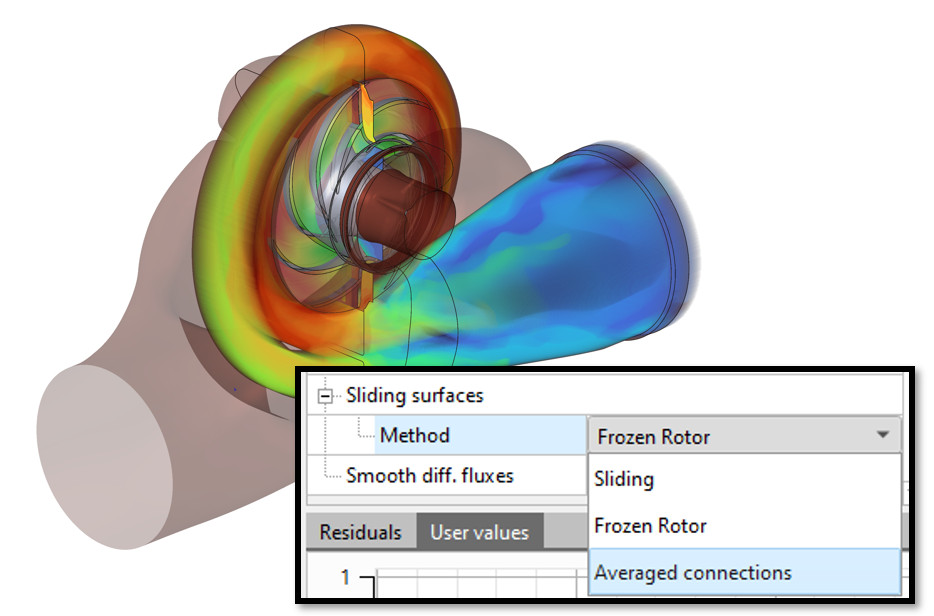

Averaged Connections for Turbomachinery Calculations

The new 'Averaged Connections' method for rotor–stator interaction achieves better accuracy than the Frozen Rotor method and is faster than the Sliding Mesh method, making it ideal for turbomachinery problems.

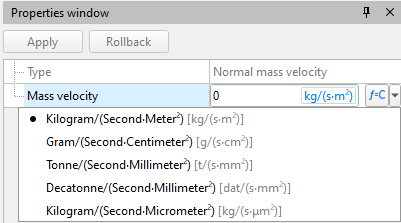

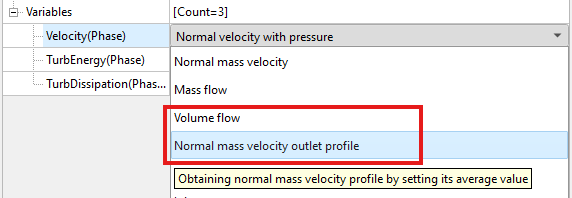

New Boundary Condition Types

Two new boundary conditions are introduced: Volumetric Flow Rate (simplifies flow specification) and Normal Mass Velocity Outlet Profile (derives variable profiles from upstream flow). These improve realism in propulsion and biomedical simulations.

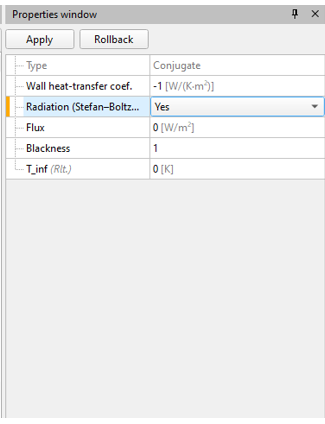

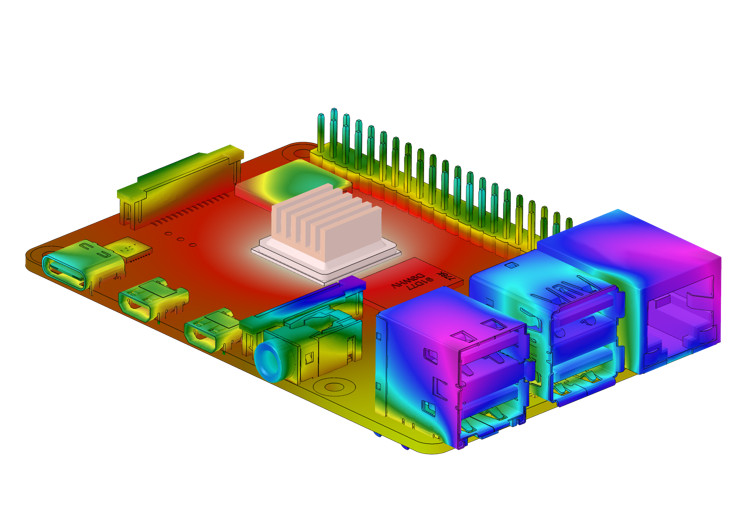

Radiative Heat Loss (Stefan–Boltzmann)

Heat loss via Stefan–Boltzmann law can now be applied directly on coupled boundary conditions, reducing computational cost compared to full radiation models.

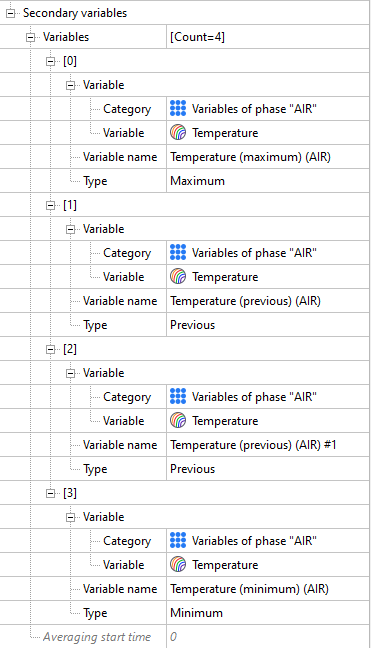

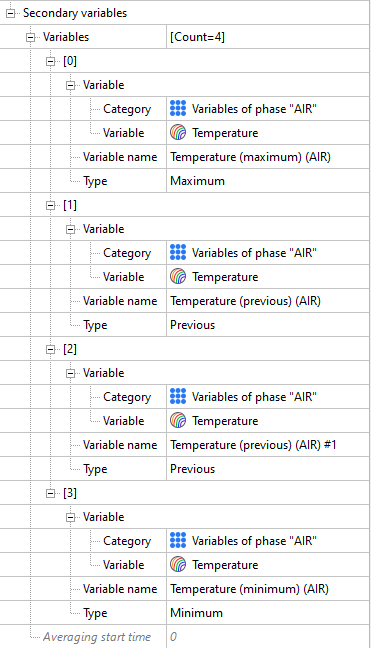

Secondary Variables

Time-averaged variables have been enhanced and renamed to 'Secondary Variables'. Users can now track max, min, average, and historical values of variables, enabling advanced post-processing and gradient analysis.

Post-Processing: Report Generator

A new report generator creates PDF, DOC, or ODT documents including project setup and results. This simplifies documentation and sharing of simulation outcomes.

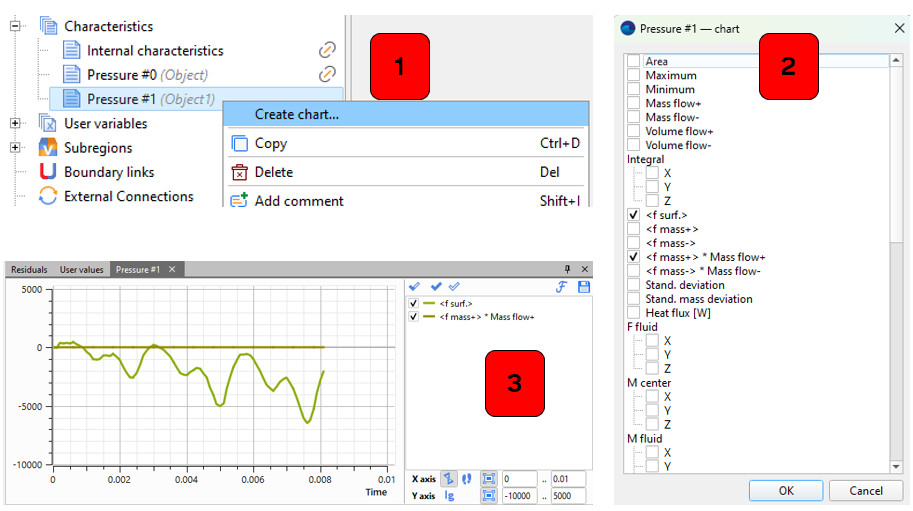

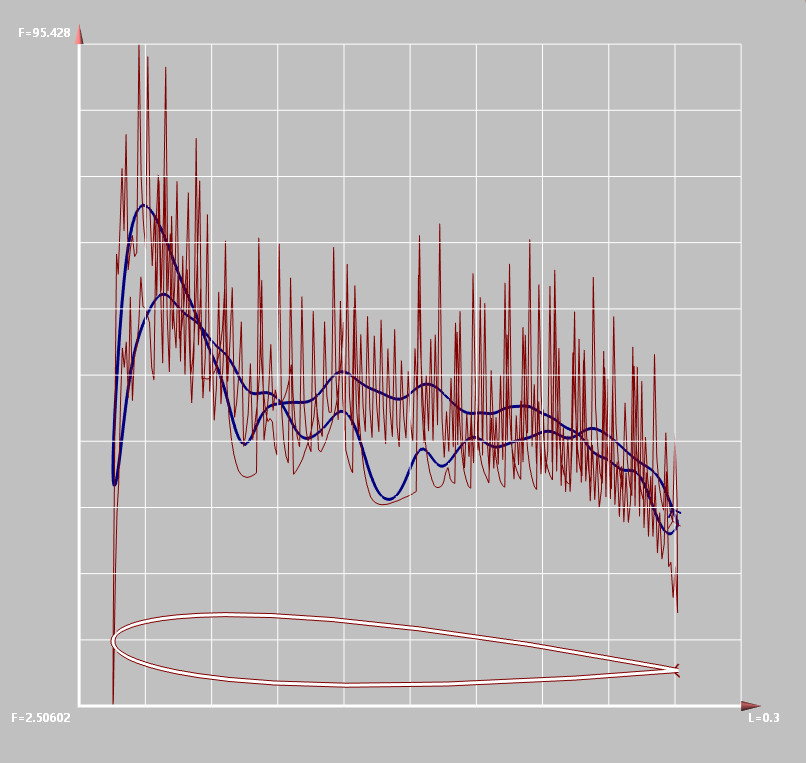

Sneak Peek to Characteristics & Curve Smoothening

Users now can quickly take a look at the time history of the characteristics that they pick. This cuts a few more clicks in the workflow. Furthermore, the users now can apply smoothening to the curves that they create in the post processing, assisting for better data analysis without export operations.

Interface Improvements

Numerous enhancements include new vector input formats, improved table editor (with interpolation and unit support), batch creation of moving bodies, automatic layer coloring, and a redesigned Preferences window.

Final Notes

This page is not the exhaustive list of the news and improvements. We recommend you to read the User's Guide & update your FlowVision to the newest release unless otherwise needed for specific reasons.