What is Gap Model?

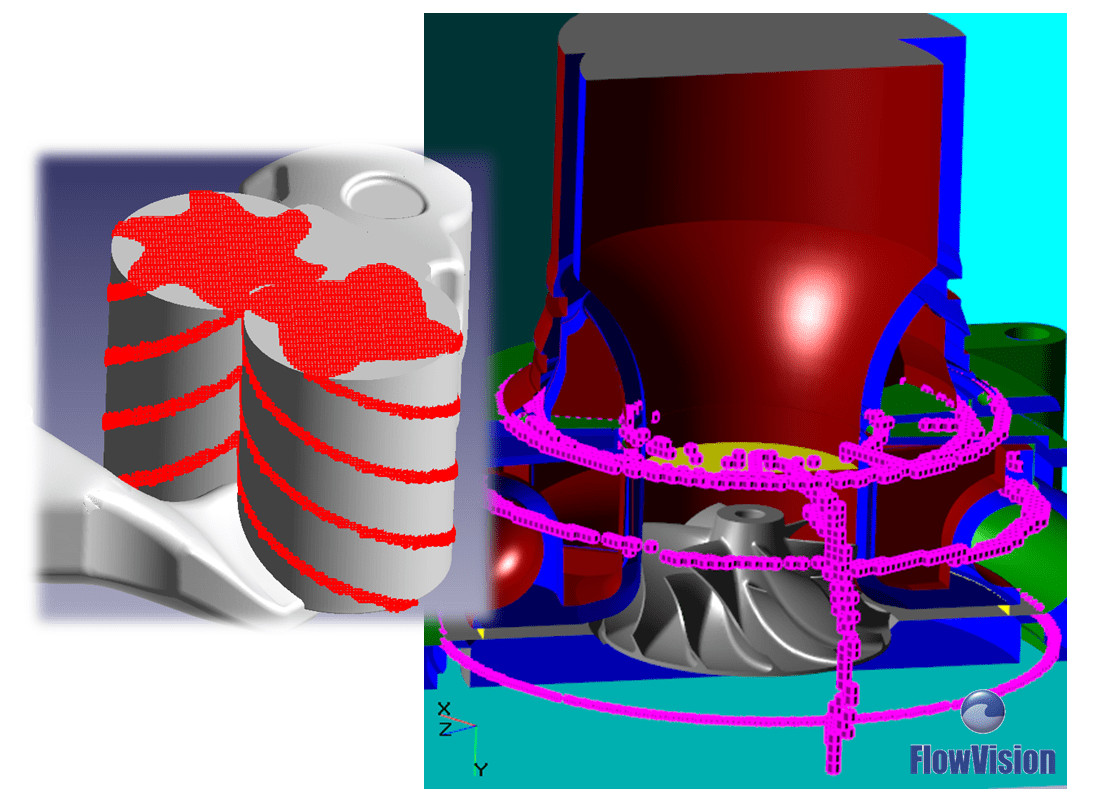

FlowVision's Clearance/Gap model provides fast and accurate solutions to problems where ultra-fine clearances exist (down to 1 micron) in the computational domain. The clearances may be dynamic or static and they will be automatically recognized by FlowVision based on the threshold defined by the user.

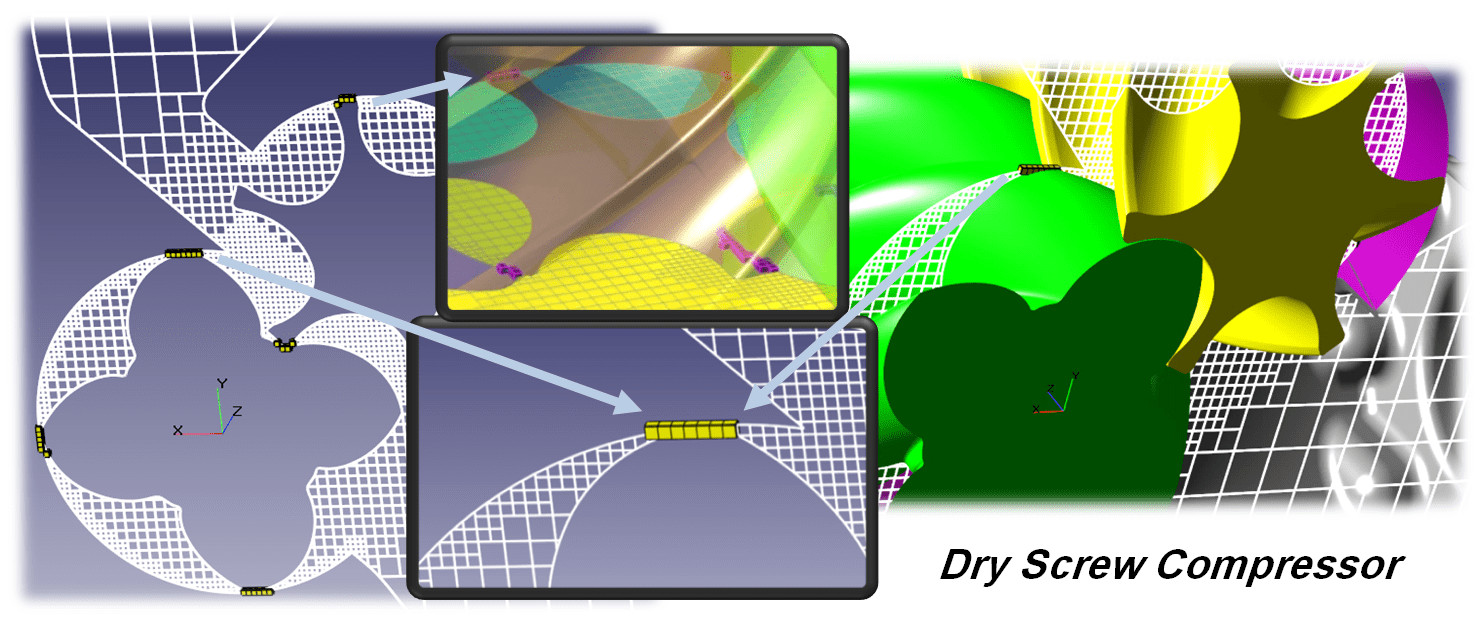

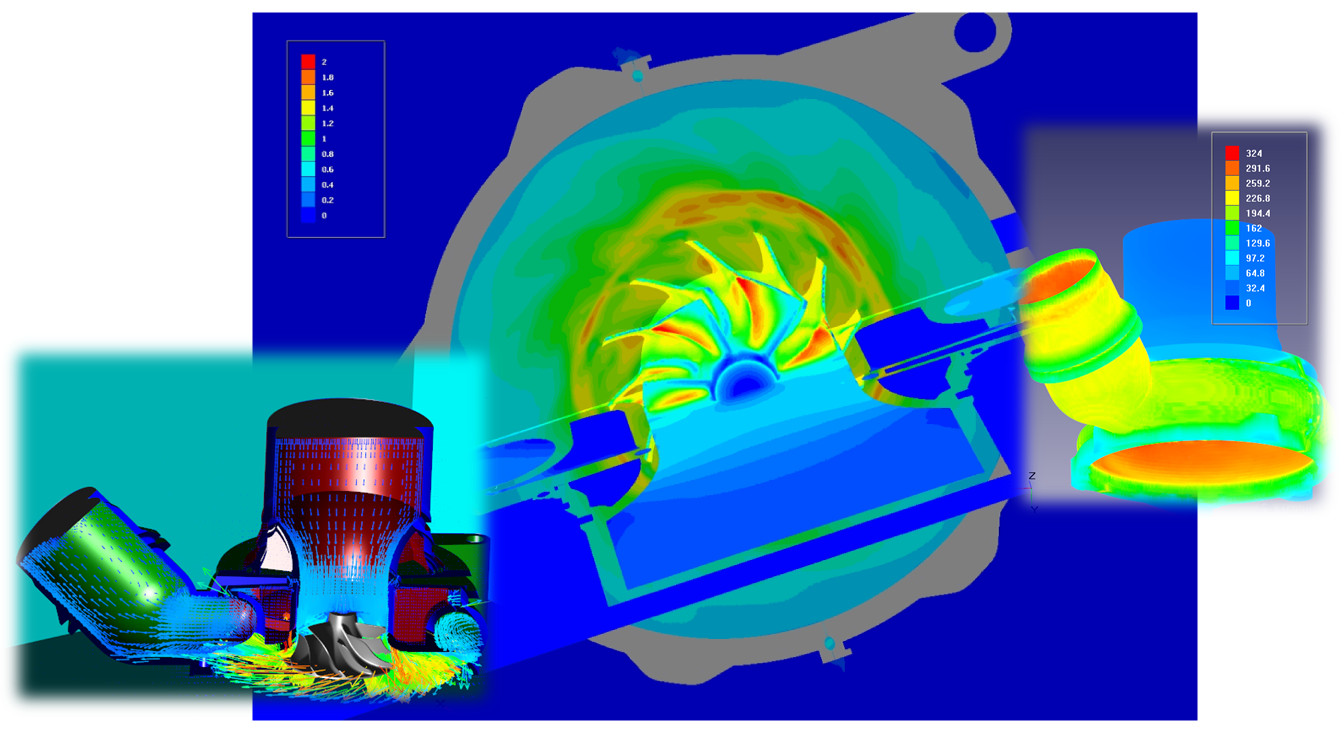

FlowVision's Gap/Clearance model is developed especially to provide fast and accurate solutions to screw compressor calculations.However, today, this feature is generalized and through gap model approach problems where scale differences up to a million can be easily addressed.

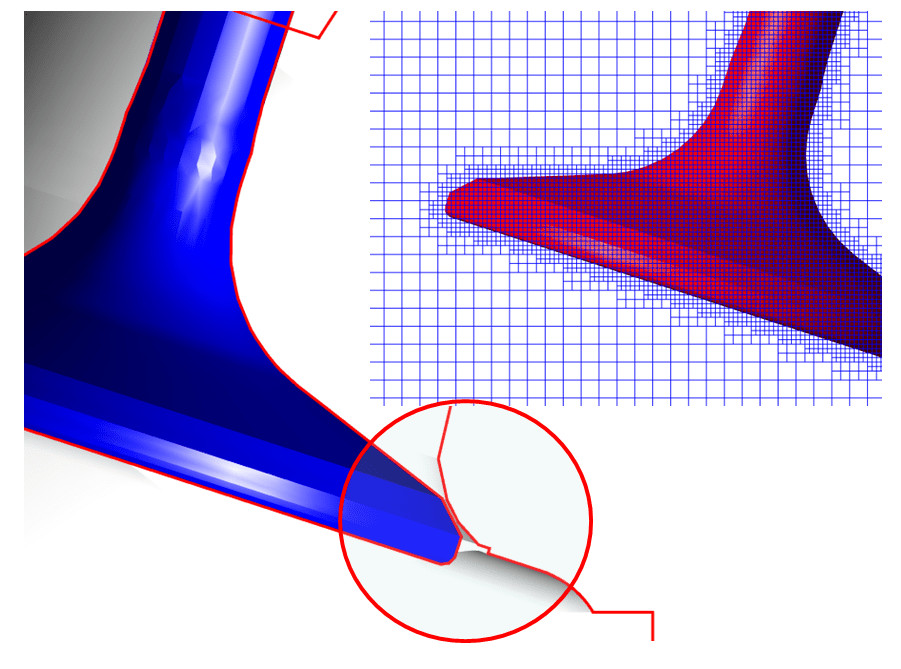

This feature is even taken a step further through recent developments, and FlowVision's Gap Model is now able to account for surface roughness and asperities which is crucial for leakage calculations in high precision sealings, oil wetting calculations etc.

No change in Automatic Meshing Routine

Users are only required to follow the normal grid generation (meshing) routine of FlowVision which consists of creating an initial Cartesian grid via Initial Grid Editor and application of geometry or solution based adaptations to achieve necessary local mesh refinements.

The complexity of the geometries used in the calculation or the number of CAD files imported usually do not affect the grid generation duration too much. A very complex geometry with tens of imported CAD files could be meshed within few minutes. The automatized Cartesian grid generation approach does not only provide fast meshing but also eliminates the user error possibility during meshing.

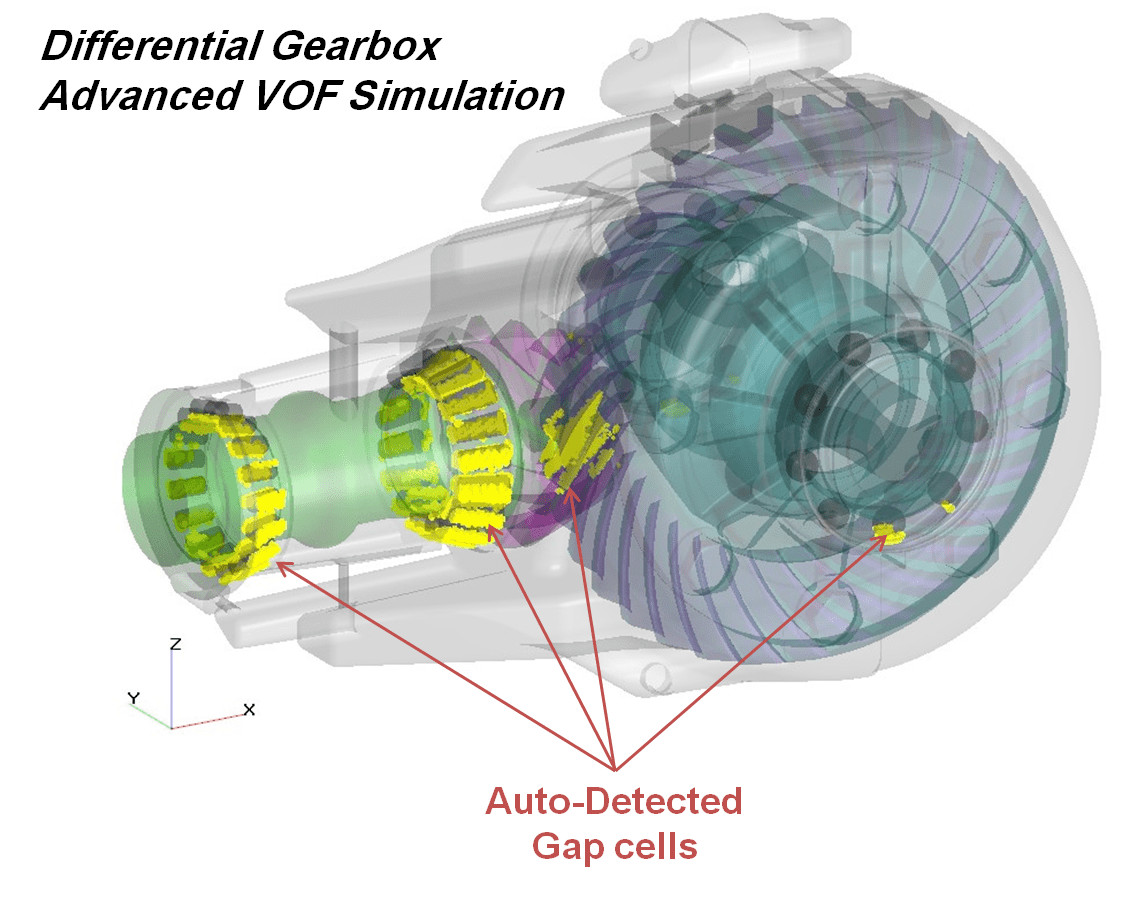

Auto-Detection of Gap/Clearance Cells and Model Application

Once the user finishes meshing, needs to introduce the threshold for the clearance encountered in the calculation. FlowVision will take care of the rest by capturing the 'Gap/Clearance Cells' and applying the modified governing equations to these cells.

In a simulation where small clearances are present, a regular fine FlowVision mesh without the gap model produces accurate results. However, with Gap Model, the same accuracy with be achieved with much less computational costs. Once the Gap Model is activated, FlowVision will automatically detect the cells corresponding to the clearance and apply the gap model. The automatized workflow, accuracy and speed makes the Gap Model unique in the world and an unrivaled revolutionary CFD tool.

Try FlowVision...

Contact us for a technical discussion.