As the consciousness of energy saving and carbon reduction and comfortable environment is paid increasing attention to, the common objective of various countries with decreasing energy is to develop and popularize high efficiency and low running noise blowers. This study uses CFD to calculate the flow field and performance of a blower and compare with the experimental measurement.

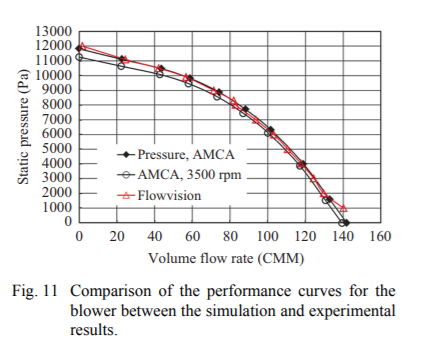

The characteristic curve of blower shows that the simulated and experimental values are close to each other, the difference between the values is only 0.4%. This analysis result proofs the CFD package is a highly reliable tool for the future blower design improvement. In addition, this study discusses the noise distribution of blower flow field, the periodic pressure output value calculated by CFD is used in the sound source input of sound pressure field, so as to simulate and analyze the aerodynamic noise reading of the flow field around the blower. The result shows that the simulated value of flow field around the fan has as high as 80.5 dB(A) ~ 81.5 dB(A) noise level and is agree with measurement (82 dB(A)). The noise level is low but has a sharp noise. According to the numerical results, designer of the blower modify the tongue geometry and remove the sharp noise.

Y. D. Kuan* J. M. Huang J. H. Wong C. Y. Chen Department of Refrigeration, Air Conditioning and Energy Engineering National Chin-Yi University of Technology Taichung, Taiwan

S. M. Lee Department of Aerospace Engineering Tamkang University New Taipei, Taiwan

C. N. Hsu CHC Fans and Blowers Company Taichung, Taiwan