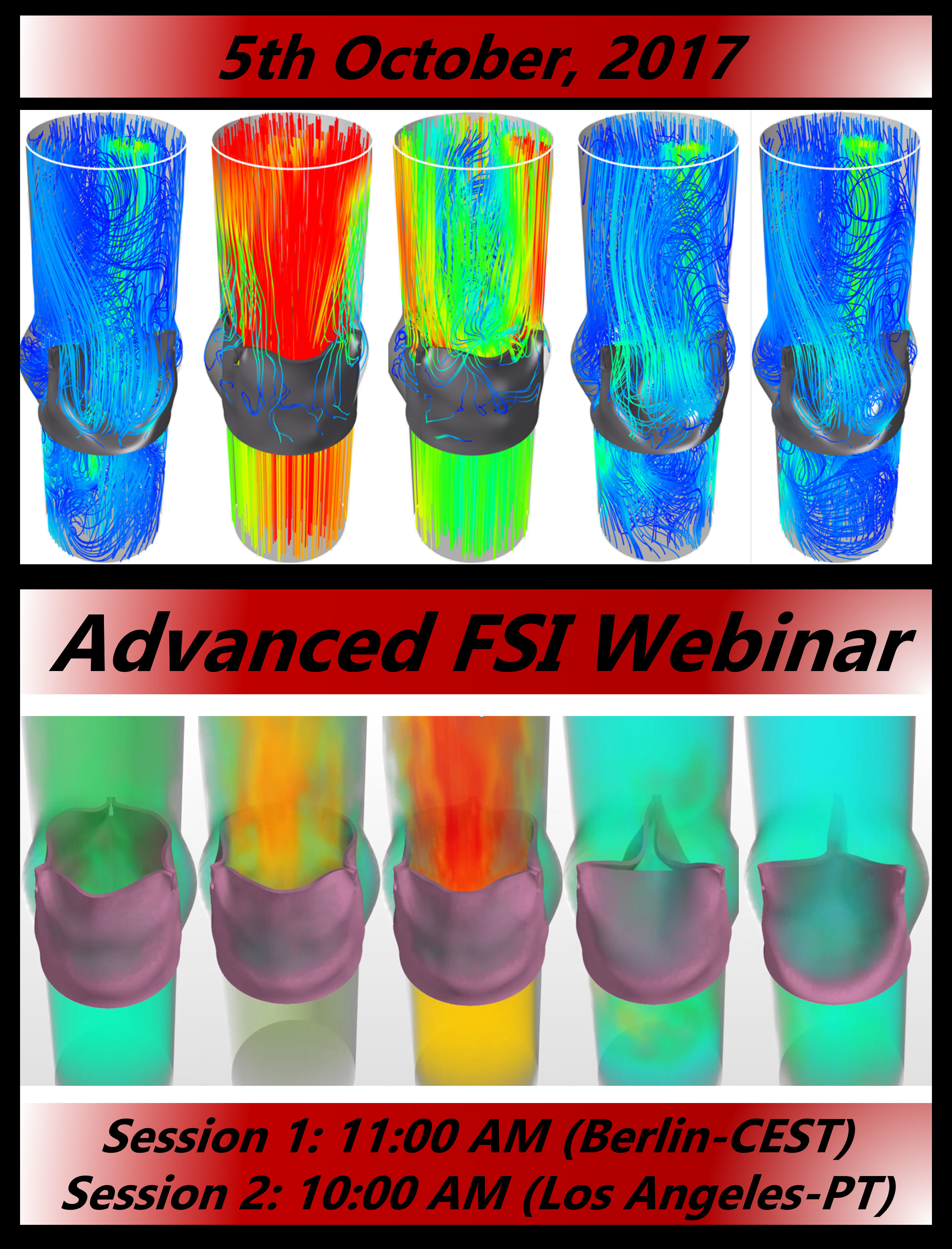

On the 5th of October 2017, We made Bio-FSI Webinar with Dr. Deepanshu Sodhani at RWTH Aachen University. Thanks again to all audience for their time and Deepanshu Sodhani the cheerful presentation... For detailed information about the Project, you can view Project website.

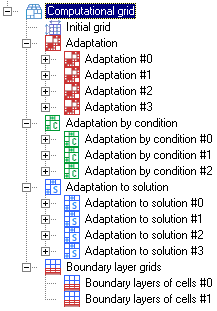

The new release includes many changes that were implemented into the program as a feedback to 30 requests from users. So we hope that FlowVision 3.10.01 will be more user-friendly.

Here are just some of the requested changes in the program:

- Captions (legends) for palettes

- The boundary condition, which allows you to set a fixed profile of velocities

- Controls for customized displaying plots in the monitor window

- The status tab now contains additional fields: number of cells of the boundary layer grid, values of convective and surface of the time step, etc.

- Now you don’t have to install MPI if use of FlowVision is assumed to be used only on one processor.

- Now it is possible to visualize streamline on surfaces.

- You have to do much less mouse clicks when working with Terminal.

- New variables have been added, Reference Pressure and Reference Temperature.

- A new layer, Computational grid section, now can be displayed by the Viewer module.

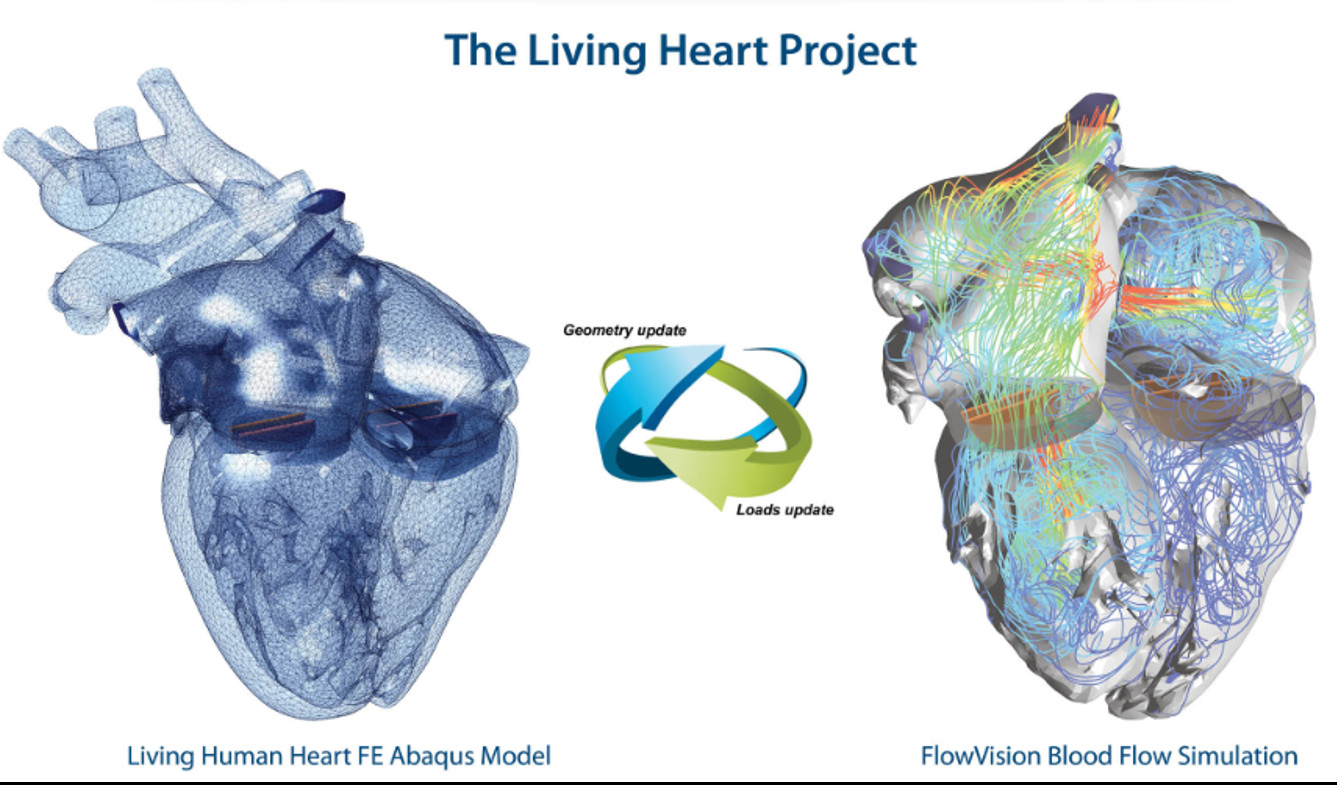

Capvidia participated in the 3rd annual Living Heart Project Members’ Meeting held in 15th May 2017, Washington DC, USA organized by Dassault Systemes.

https://www.3ds.com/events/living-heart-project-members-meeting/

The Members’ Meeting provided a platform to connect members, share perspectives, challenges and goals, and identify complimentary approaches and technologies. Thanks to the attendance of a wide audience including distinguished speakers from US Food and Drug Administration and leading institutions such as West Virginia University Cardiac Innovation Heart and Vascular Institute, the event served as a leading forum for illustrating and setting the translational course for Cardiovascular Care through advanced simulation technologies.

May 15 – 18, 2017, Chicago, IL – Capvidia participated as an active sponsor of the Simulation Community Conference “Science in the Age of Experience 2017” organized by Dassault Systemes SIMULIA.

Presentations covering simulations performed by Abaqus – FlowVision FSI approach:

- Fluid Structure Interaction in a Beating Human Heart (Capvidia NV & 3DS SIMULIA)

- FlowVision & Abaqus 2-Way Strongly Coupled FSI Simulation of Automobile Tire Aquaplaning (KENDA Rubber Ind. Co. Ltd. & Samwell Testing Co. Ltd.)

May 9 – 12, 2017, İstanbul – AKANA Mühendislik, Capvidia business partner and FlowVision CFD software representative in Turkey, participated at IDEF’17.

During the fair; Akana stand (#1408) has been open to visitors in Hall 14. An international community of design and simulation engineers from various defence companies have visited the stand for gaining insights about unique capabilities of FlowVision CFD software and its applications, mainly in the defence industry.

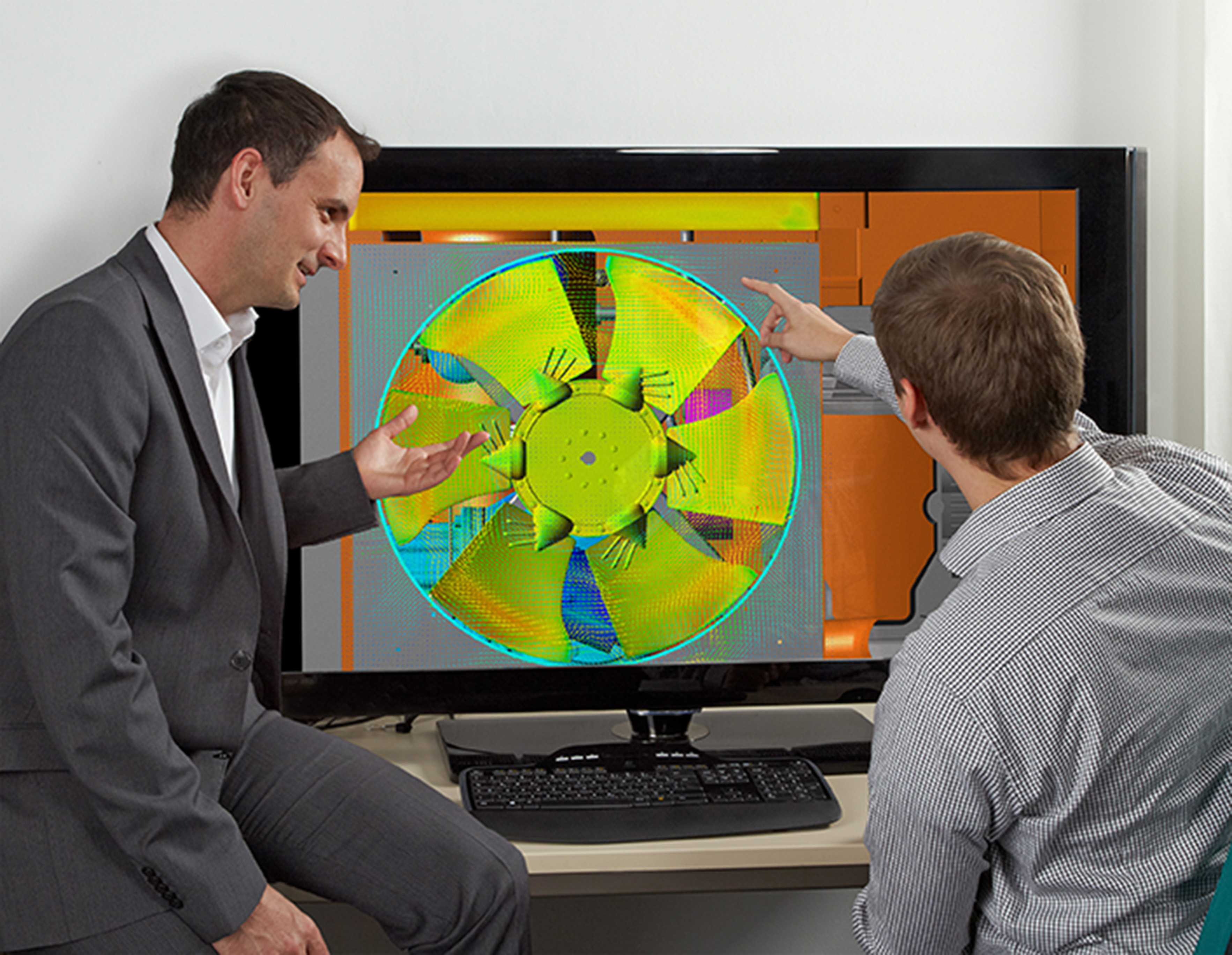

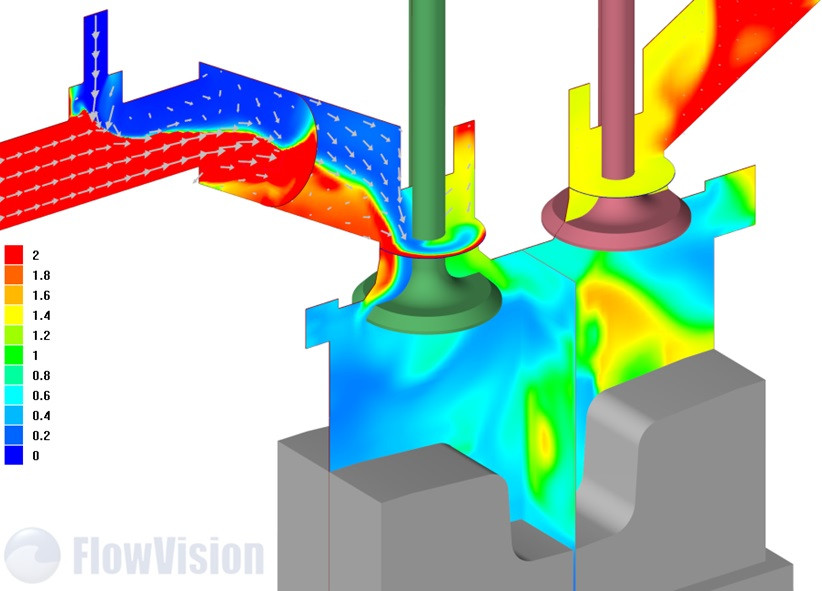

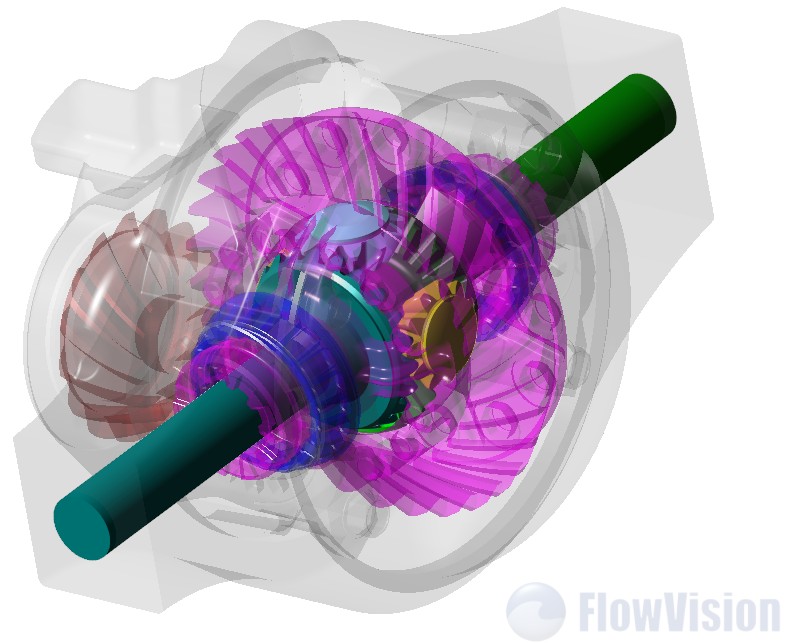

The CFD software package FlowVision was used for the most complicated calculations of oil distribution in the crankcase of the leading axle of the KAMAZ truck. This pilot project was successfully completed in close cooperation between the specialists of TESIS and KAMAZ.

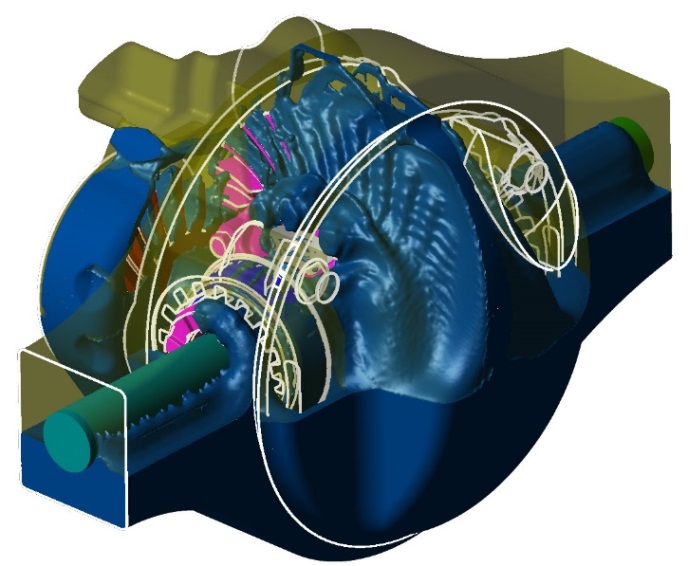

Geometrical model of a fragment of a crankcase of the driving axle

Based on the three-dimensional CAD-model of the crankcase created by the designers of KAMAZ company, the specialists of TESIS have developed a mathematical model which describe the flow of oil partially filling the crankcase volume under the action of rotating structural parts and gravity field. The calculations have been performed together for various modes of operation of the simulated unit differing in the operating temperature of the transmission oil and the angular velocities of the rotating parts, the driving and central wheels, and also the satellites.

The oil distribution in the crankcase volume

The analysis of modeling results carried out by specialists of KAMAZ and TESIS made it possible to trace the dynamics of movement and distribution of oil in the crankcase volume, as well as to evaluate the effectiveness of lubricating the surfaces of structural parts.

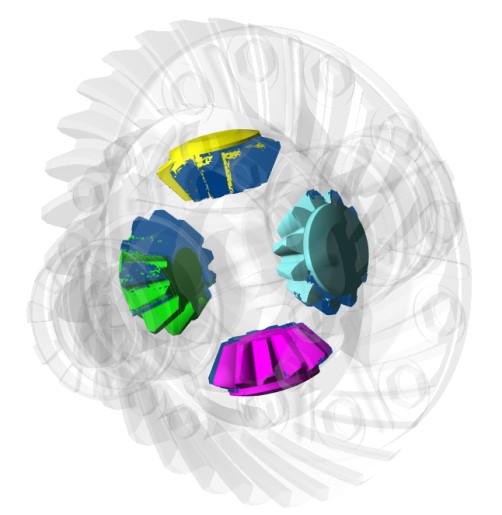

Distribution of oil on the surfaces of satellites

Based on expert analysis of the results of calculations, conclusions were drawn about the adequacy of the calculated design model and the possibility of using the FlowVision software package to solve the issues and design basis for the lubrication of complex mechanical systems for KAMAZ vehicles. The developed approach gives the designer the opportunity at all stages of design to obtain and analyze reliable and comprehensive information on the characteristics of the lubrication system.

Successful solution of the task was made possible thanks to the creative approach and well-coordinated work of the pilot project team - specialists of KAMAZ and TESIS, as well as a number of innovative technologies and unique functionality of the software package FlowVision, which include:

- Direct import of the geometry of modeled object from the CAD-system using a wide list of supported formats;

- Automatic generation of a computational grid with local dynamic adaptation, which makes it possible to obtain an exact solution with minimal costs for preparing the task for calculation and for the required computing resources;

- Simulation of the complex motion of a system of solids in liquid according to a given law or under the action of hydrodynamic forces;

- Simulation of flows in the gaps without the construction of a detailed mesh inside the gap - calculation of the flow of oil in the channels formed by the gears of the rotating wheels, satellites and bearings;

- Extensive opportunities for the presentation and analysis of modeling results:

- A realistic representation of the distribution of oil in the volume of the constructions;

- Visualization of surfaces for lubricated parts;

- Non-stationary circulation of oil in the lubrication system;

- Distribution of pressure on the walls of the constructions;

- Field of velocities in the calculated domain.

Based on the results of the pilot project, KAMAZ company and TESIS company agreed on further long-term cooperation with the aim of evolution a computational model and creating new modern methods for modeling physical processes based on FlowVision and ABAQUS software packages for use in the design of various KAMAZ vehicles.

The 15th International Forum «Engineering Systems», organized by TESIS company, was held on April 11-12, 2017 in the Moscow City business center. The Forum included three conferences:

- Computational fluid dynamics (CFD): FlowVision users’ meeting

- Finite element analysis (FEA): SIMULIA Abaqus Users’ meeting

- Conference «Modeling of metal forming and heat treatment processes in DEFORM and JMatPro»

At the FlowVision users’ meeting International exchange of experience at the forum

Representatives of the largest manufacturers of Russia shared their experience of using CAE-tools in the design of products, assemblies and units. Participation in the forum was made by RSC Energia, OKBM Afrikantov, KAMAZ, TMKB Soyuz, JSC Titan-Barrikady, CDB WT Rubin and others.

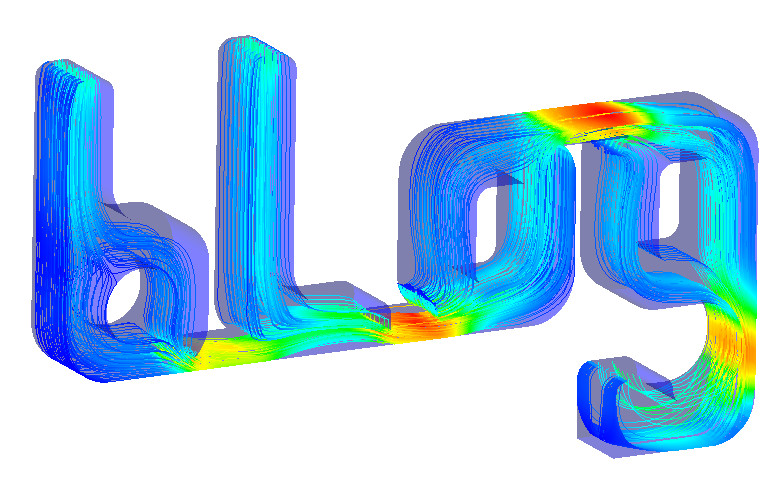

FlowVision Development and Support Teams are now sharing their great expertise with their users through a FlowVision dedicated online blog.

Enter the website below and discover which topics our experts have already addressed: https://fv-tech.com/index.php/en/16-blog-how-to-use-flowvision

Alternatively, you can find link to FV Blog in Support section of our global website: https://fv-tech.com/index.php/en/support

Additionally, please feel free to contact us if you have some specific topics on your mind that should be given priority for finding its place in the FlowVision blog.

Have a nice reading…

TM Profs has joined our worldwide channel for promotion of Capvidia software products in the Netherlands.

FlowVision CFD software, being product of Capvidia NV, is being represented by various value added resellers throughout the world. Today, we are glad to announce that a new partner has joined our channel. TM Profs, having headquarters located in Eindhoven, has started working as an official FlowVision reseller in the Netherlands region.

Please check contacts section of our web-site where information about all of our resellers is listed and feel free to reach any reseller in your territory or in your language. As a whole of extended FlowVision family, we are always more than pleased to help you with demonstration of our software and integration of our capabilities into your engineering design cycles.

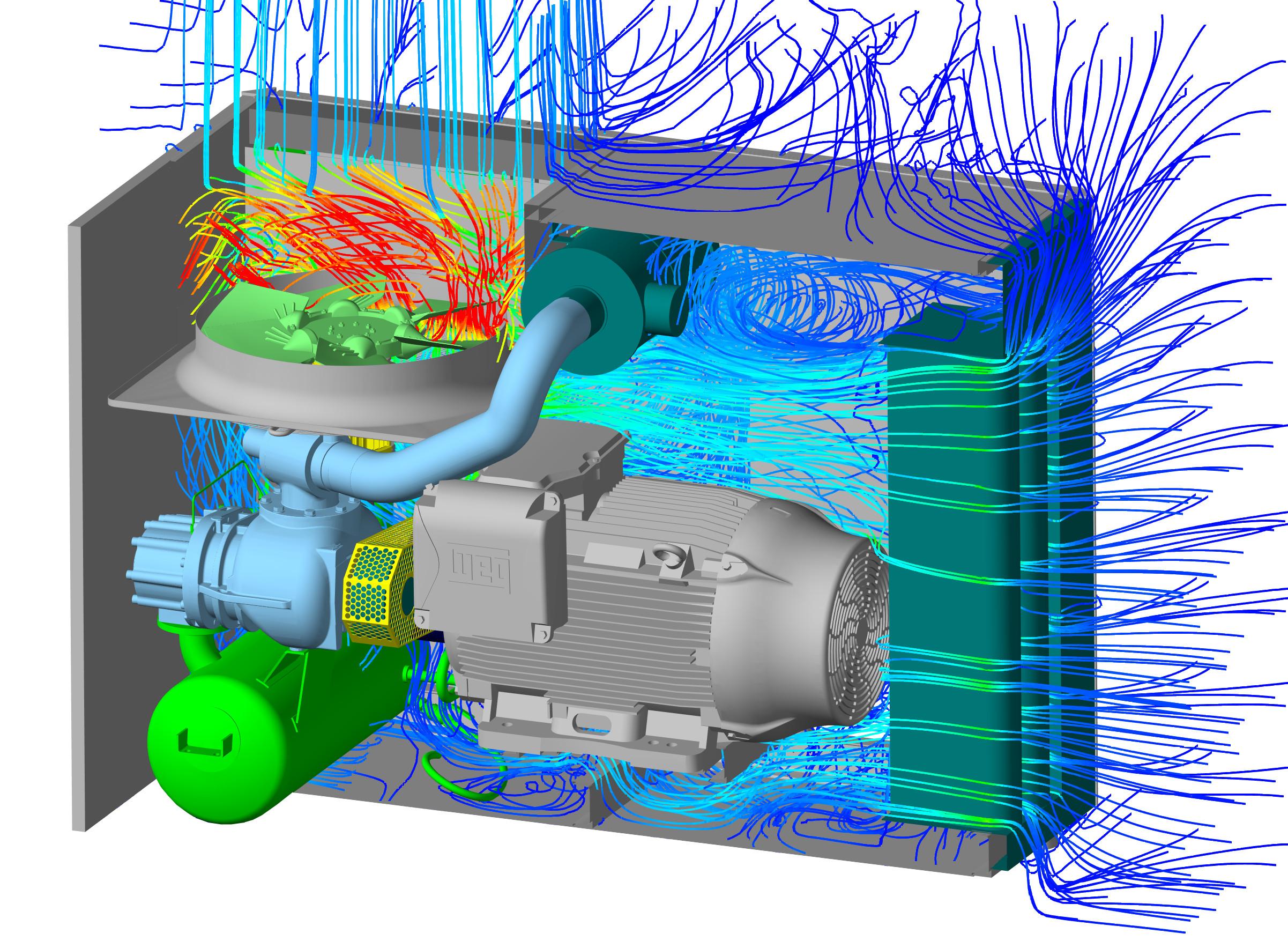

Small and medium-sized companies are interested in use of engineering software and high-performance computers. The EU’s project CloudFlow provides the both possibilities. 46 partner organizations from 13 European countries are working together in this project coordinated by the Fraunhofer Institute for Computer Graphics Research IGD. The project provides access to the numerical simulation software for small and medium-sized companies with using cloud computing on the CloudFlow platform. In this solution the existing servers provides high computational performance for solving difficult problems (High Performance Computing, HPC). Customers pay for computational power and the software only when they use these resources via Internet. Use of cloud technologies allows the customers to:

- use the software and infrastructure of high performance computations in a cost-effective way

- solve high dimension problems (complex part assemblies)

- carry out several optimization projects on supercomputers in a parallel mode

May 23 – 25, 2016, Boston – Capvidia is participating as an active sponsor of the Simulation Community Conference “Science in the Age of Experience” organized by Dassault Systemes SIMULIA.

During the Conference; the unique integration of FlowVision and Abaqus for the solution of FSI (fluid-structure interactions) problems will be demonstrated and Capvidia will show-up at different activities:

- Capvidia booth will be open to visitors in the Exhibition area during the Conference days…

- Presentations about FlowVision during ‘Integrated Solutions’ sessions:

- FlowVision – Abaqus Integrated FSI Solutions

- Our Contribution to Living Heart Project by SIMULIA

- Hands-On Software Demonstration; A Sample FSI Application with FlowVision and Abaqus

This special event will be held at the Boston Marriott Copley Place in May 23-25, 2016. For up-to-date information and detailed agenda, please visit event page on SIMULIA website.

Capvidia, as a member of Automation Alley, is organizing (8th June) a seminar where participants are expected to learn how to take advantage of FlowVision's unique capabilities such as automatic meshing with associative CAD geometry, use of moving and flexible bodies, and solving heavily coupled multi-physics co-simulations with SIMULIA Abaqus.