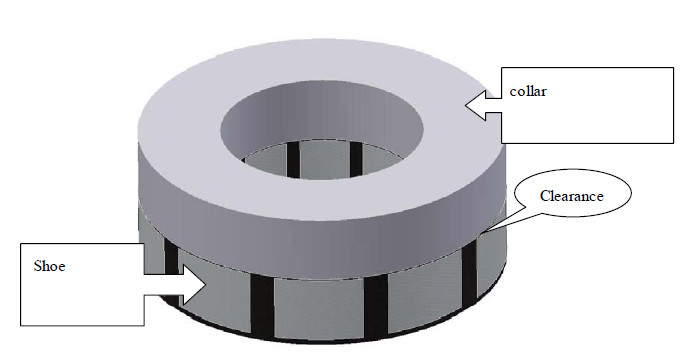

Lift force formation in a thrust bearing of 800-tons rotor of electric power station is discussed in the given paper. The problem is solved numerically. Direct coupling between finite-element system Abaqus calculating stress and strain state of an bearing parts and finite-volume system FlowVision-HPC calculating oil flow in gap between a collar and a shoe of bearing is used. The shape of the gap between the shoe and the collar, the clearance value, the moment of the friction force, and the temperature distribution of oil over the clearance are determined.

Ricky Chen, Taiwan Power Company, Taiwan

A. Aksenov, A. Shishaeva, TESIS Ltd, Russia/CAPVIDIA, Belgium,

Frank Kuo, Samwell Company, Taiwan

SIMULIA Customer Conference 2010, Page1/9