The first valve stem seal was invented in 1958. It was made up of Buna-N (NBR) Elastomer Body, Ring retainer, Teflon insert working in a 400°F temperature environment. In the early days before the invention of valve stem seals, there was higher oil consumption, excess blow by through the valves and high wear of the valves.

The design of the valve stem seal depends on several factors since the valve stem seal works in a very complex environment. Yet the primary function of the seal is to meter the oil in the right quantity against the pressure. It resists flowing oil to vacuum. Too much oil causes extensive emissions and deposits, while too little oil causes valve seat, face and guide wear. Therefore the solution is hydrodynamic lubrication. Oil metering rate is dependent upon the valve stem diameter, oil viscosity, and stem speed.

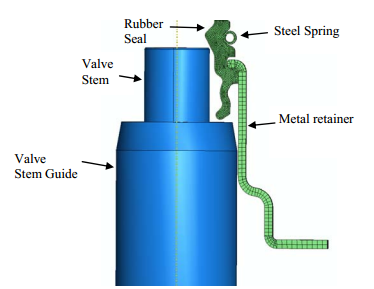

There are several other factors that affect the oil flow rate in the valve stem seal. One of the main factors that affect long term performance of the seal is the material aging due to oil, heat and temperature, which produces lots of challenges in the design process. Since the lab aging of the seals during the design process cuts into the design time, numerical processing is needed to predict the oil flow rate. Finite element analysis (FEA) shows how the seal deforms under installation and working conditions of the engine and also determines the contact pressure between the seal and the stem that in turn determines the oil flow rate. FEA can also be used to observe the difference in contact pressure due to the changes in materialproperties due to aging. Computational fluid dynamics (CFD) methods provide calculations of the oil metering rate in channel formed by stem and deformed seal. But FEA or CFD techniques alone are unable to predict the amount of oil flow due to pressure changes between the top and bottom of the seal. Therefore the Fluid Structure Interaction (FSI) techniques is necessary to provide a comprehensive study the oil flow rate in the seal.

The FSI technique uses ABAQUS to predict the stem seal deformation and FlowVision to calculate the oil flow. Two-way interaction between ABAQUS and FlowVision is managed by the Multi-Physics Manager. The FSI technique couples the CFD and FEA simulation domains. The link to ABAQUS is implemented using Abaqus user subroutines and does not involve any other intermediate data structures.

A. Aksenov, K. Iliine TESIS, Russia

T. Luniewski, Capvidia, Belgium

T. McArthy, F. Popielas, R. Ramkumar

DanaCorporation,USA

ABAQUS Users’ Conference 2005, Page1/14