An approach for solving Fluid Structure Interaction in aerospace application is presented in this paper. The proposed approach is based on the two-way coupling between CFD code FlowVision and FEA code ABAQUS. The codes are coupled directly without using any 3rd party software or intermediate

structure.

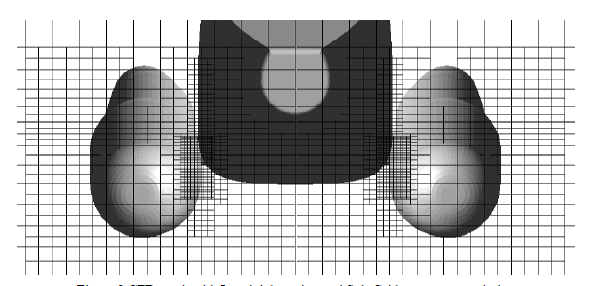

A direct link offers a full control over the load transfer and interpolation error free data exchange between the codes. The direct link is implemented using special meshing techniques (submerged meshes in FlowVision). FE mesh is subtracted from the Cartesian CFD mesh; all links between CFD mesh cell and outside faces of the finite elements are preserved. Node displacements are transferred directly between FlowVision and Abaqus without any interpolations. The above approach is illustrated with simulation of helicopter emergency landing on the water surface (helicopter equipped with flexible landing ballonets). The simulation objective is to estimate maximum loads on the helicopter hull caused by splashdown. The ballonets should absorb some of the impact and decrease acceleration on the helicopter crew. Results of two simulations are compared: helicopter lands on a rigid surface (ground) and on the still water surface (splashdown).

Andrey A. Aksenov, Kirill A. Iliine and Vladimir V. Shmelev

WEST-EAST HIGH SPEED FLOW FIELD CONFERENCE, 19-22, November 2007, Moscow, Russia, Page 1/9